Corrosion behavior of post-tensioned pre-stressed concrete structures

BY Eng. BHJ Pushpakumara,

Generally, the steel embedded in concrete can be considered to be highly resistant to

corrosion since the hydroxides produced during the hydration process of concrete form a

passive protective iron oxide film (i.e. Fe 2 O 3 ) around the reinforcement bars, leaving them in

an environment at or above a pH of 10.5. This iron oxide layer is considered to passivate the

steel against corrosion and for the initiation of corrosion, this passive layer has to be de-

passivated. The de-passivation could happen mainly due to two reasons, namely chloride

ingression and the carbonation process.

Sri Lanka is an island surrounded by the Indian Ocean and therefore has thousands of

Reinforced Concrete (RC) structures along the coastal belt. The chloride ions-induced

corrosion is one of the main reasons for reducing the design service life of these RC

structures. If the chloride content near the steel increases up to a specific level that is

necessary to sustain local passive film breakdown, the protective layer de-passivates and the

corrosion process is initiated. This particular chloride content is defined as the chloride

threshold level. With the initiation of corrosion, the corroded material will be first occupied

into the pore spaces between the concrete and the embedded steel reinforcement. It is

assumed that the corrosion products are mainly rust (Fe 2 O 3 .3H 2 O), red rust (Fe(OH) 3 ), and

black rust (Fe 3 O 4 ). These products have a higher volume than steel and therefore cause

volume expansion in concrete inducing tensile stresses which lead to concrete cracking. This

accelerates the corrosion process as the cracks provide ambient water and oxygen to the steel

reinforcement resulting in production of more corroded material.

Sri Lanka is a country that started a rapid development in the infrastructure sector and large-

scale construction work in the recent past, and therefore, is now moving towards Pre-stressed

Concrete (PC) structures from RC construction. Hence, PC construction can be considered a

relatively new construction technique for the Sri Lankan construction industry and no studies

have been done regarding the corrosion behaviour of PC structures in the country. A large

number of factors affect the corrosion of concrete structures that the process is too complex

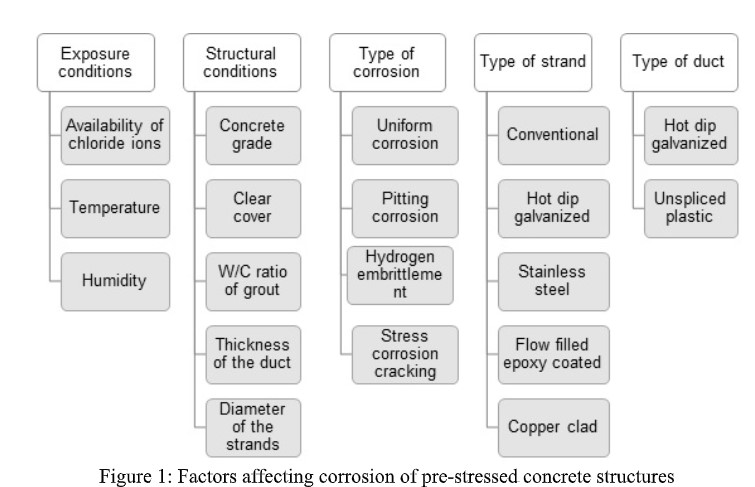

and is yet to be fully clarified. Figure 1 reports the most prominent among many factors that

affect the corrosion process.

Unlike in RC structures, the pre-stressing strands in post-tensioned pre-stressed concrete

structures are covered by a grouted duct. This phenomenon is supposed to increase the time

to initiation of corrosion in pre-stressed concrete structures than in RC structures. In fact, the

corrosion initiation of pre-stressed concrete structures could be further divided into three

stages; the time for corrosive ions to reach the duct, the time for the duct to corrode, and the

time for corrosive ions to reach the strand through the grout. However, because of the high

stresses in pre-stressed strands and the smaller diameters, the corrosion propagation is

accelerated. Even small corrosion pits could cause a strand to fracture, compared to

conventional reinforcing that may rust to virtually nothing before breaking.

The rate of travel of corrosive ions through concrete to reach the duct and the rate of travel of

corrosive ions through the grout to reach the tendon could be different owing to different

diffusion coefficients of chloride ions in concrete and grout. Further, the duct acts as some

sort of a protective layer for the strands which in turn can influence the corrosion initiation

time of the pre-stressed concrete. Unspliced plastic ducts showed better protection of the

strands or bars when compared to unspliced galvanized steel ducts. In the hot dip galvanized

duct the zinc coating is a sacrificial element, which means that once the entire zinc coating

has fully reacted, the steel will begin to corrode. It has been experimentally proven that the

corrosion rate increases with the increase of stress in the strands, in an approximately linear

manner. Furthermore, with the increase of stress on the strands, the tendency of it to have

brittle fractures increases, which may lead to the separation of strands. On the other hand, as

the level of post-tensioning or concrete pre-compression increased, the corrosion protection increased.

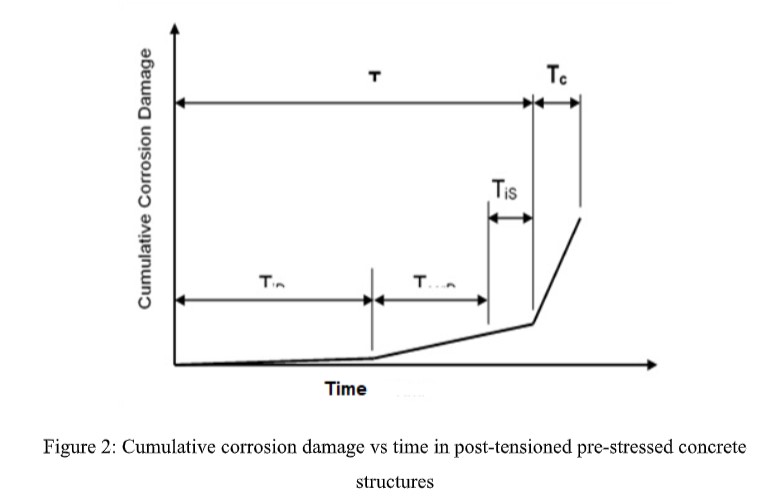

The corrosion process of RC structures has been divided into three stages namely, the

corrosion initiation stage, the de-passivation stage, and the corrosion propagation stage.

However, the corrosion process of post-tensioned pre-stressed concrete structures could be

divided into four stages namely, corrosion initiation of the duct (T iD ), corrosion of the duct

(T corD ), corrosion initiation of the strands (T iS ) and corrosion propagation of the strands (T cor )

as shown in Figure 2. The main difference was that the corrosion initiation time is divided

into three sub-stages in PC corrosion and that the corrosion initiation time is longer than that

of RC corrosion. However, the corrosion propagation time of PC structures was very low

compared to RC structures. The corrosion propagation time was defined as the time from the

initiation of corrosion of the strand till the structural failure. This was mainly due to the fact

that unlike in reinforced concrete structures, brittle fractures could occur in steel strands of

pre-stressed concrete structures, which may lead to sudden catastrophic failures. Moreover, it

has been found that smaller cross-sectional areas of steel strands under very high stresses are

more susceptible to brittle fractures.

Much research has been conducted to model the corrosion behaviour of RC structures, but research conducted on the corrosion behaviour of PC structures is very few. The usual practice is to predict the corrosion damage in PC structures, in a similar way to that of reinforced concrete structures. However, this might not be accurate due to the fact that pre- stressed strands are embedded in a grouted duct and also due to the fact that pre-stressed strands have smaller section sizes under higher stresses. Therefore, there is a dire need for a model which could predict the corrosion damage in the pre-stressed concrete structures in a more reliable manner.

Eng. BHJ Pushpakumara

Eng. BHJ Pushpakumara

Senior Lecturer, Department of Civil Engineering, Faculty of Engineering,

General Sir John Kotelawala Defence University-Southern Campus, Sooriyawewa, Sri Lanka