Compressed Stabilized Earth Blocks with Construction Waste and Coconut fiber

BY Eng. (Dr.) S. Nirosha Malkanthi

Introduction

Burnt bricks and cement-sand blocks are the main construction materials used in masonry. In fact, the use of Sun-dried clay bricks as a building material has a history of more than 6,000 years. The availability of quality raw material for the production of bricks and cement blocks is becoming scarce; hence, many alternatives have been developed as walling materials. Historically, earth is a very old building material which has been used in different forms like mud, adobe, rammed earth and burnt bricks. Compressed Earth Block (CEB) is a building material made with damp soil by compressing at high pressure. They are also known as pressed earth blocks. The raw material to form CEB is usually a mix of fairly dry inorganic subsoil, non-expansive clay and aggregate. A mechanical press is needed to form compressed earth blocks. Compressed Stabilized Earth Blocks (CSEBs) are an extension of CEB adding a chemical binder such as Portland cement. Interestingly, CSEB has been gaining more popularity due to its sustainability and environmental friendliness. Further, the followings are some advantages and features of CSEBs.

Environmentally Friendly: CSEBs are made from natural and locally available materials, such as sandy soil, gravel and stabilizers like cement or lime. They have a lower carbon footprint compared to other construction materials, as the manufacturing process consumes less energy and releases fewer greenhouse gases.

Renewable and abundant raw materials: Soil and gravel, the primary raw materials for CSEBs, are abundant renewable resources. This lessens the need for mining and substantial extraction of nonrenewable resources.

Energy-efficient production: Because CSEBs are compressed rather than burnt in a kiln like for traditional bricks. Hence the production process consumes little energy. Therefore, the production process is an enhanced energy efficient with minimized emissions.

Cost-effective: Local production of CSEBs utilizes readily available soil and stabilizers, which helps to reduce the cost of material transportation. This makes them a cost-effective option, particularly in rural locations where transportation can be costly.

Durability: CSEBs, when properly manufactured and stabilized, CSEBs can have good durability and strength, making them suitable even for load-bearing applications in construction.

Sound Insulation: CSEBs can provide reasonable sound insulation due to their solid construction and density. This makes them suitable for buildings in noisy environments or areas where soundproofing is important.

Thermal Insulations: CSEBs generally have better thermal insulation properties compared to traditional concrete blocks. This can help to maintain a more comfortable indoor temperature, reducing the need for excessive heating or cooling.

Local community engagement: CSEB production can be a community-based activity, involving local labour and promoting skill development. This can positively impact the local economy and create employment opportunities.

Low water consumption: The production of CSEBs typically requires less water compared to fired bricks contributing to water conservation efforts.

Despite many benefits, there are also some challenges associated with CSEBs such as ensuring proper soil selection, stabilizing techniques and quality control production. However, as sustainable construction practices gain momentum, innovations, and improvements in CSEB technology are likely to make it an even more viable option for environmentally conscious construction projects.

To improve the qualities of CSEB, a study was conducted using building construction waste to change the soil grading according to the particle packing optimization and coconut coir as a reinforcement.

CSEB with Construction Waste

This article reports the development of CSEBs using abundant soil and construction waste. The objective was to create eco-friendly construction materials that are cost-effective and offer improved strength and durability.

The following are the key points considered for CSEB production.

- Soil Selection: The soil selected from a borrow pit near the Karapitiya area of the Southern region of Sri Lanka has a clay percentage of nearly 19% and a plasticity index of 3.5%. making it slightly plastic. Previous research suggests that soil with a plasticity index of less than 15% are suitable for CSEB production, indicating that the chosen soil is appropriate for this purpose.

- Cement Stabilization: Ordinary Portland Cement was added to the soil to stabilize it. The study used a cement-to-soil ratio of 10% by weight as this amount has been found to achieve the required strength while maintaining cost-effectiveness.

- Clay percentage reduction: To improve the strength and durability of CSEBS, the clay percentage in the soil was reduced. This was accomplished by incorporating larger particles obtained from building construction waste, primarily crushed concrete waste. By optimizing particle packing, the soil was modified to better suit the theoretical particle distribution curves.

- Coconut coir reinforcement: Coconut coir, especially the Bristle fiber type was used as a reinforcement material in CSEBs. Coconut coir fibers are known for their strength and length making them suitable for enhancing the block’s properties. The diameter of the coir used in the study is approximately 0.2 mm.

After reviewing various publications, the coir length was determined to be 2cm, 4cm, 6cm, and 8cm, with coir amounts of 0.1%, 0.2%, 0.3%, 0.4%, and 0.5% of the total weight of the dry soil. To obtain a straight fiber bundle, the coir was combed with a wire brush to eliminate undesirable particles adhering to the fiber. Then, using a knife or scissors, these were chopped into predetermined lengths. All the materials were mixed by weight. For 10kg of soil, 6.46kg of construction waste and 1.0kg of cement were used. Water addition was 8%-10% of the soil weight. The cubes (150 x 150 x 150) mm were cast, and the properties of the cubes were tested. For each test, three specimens were used. The optimum coconut coir combination which showed the optimum desirable properties was selected and using that combination, industrial scale (350 x 100 x 175) mm blocks were produced and the properties of it were tested. Block preparation and testing were done following SLS 1382 Part 2: Specification for Compressed Stabilized Earth Blocks-Test Methods.

Properties of Manufactured CSEB

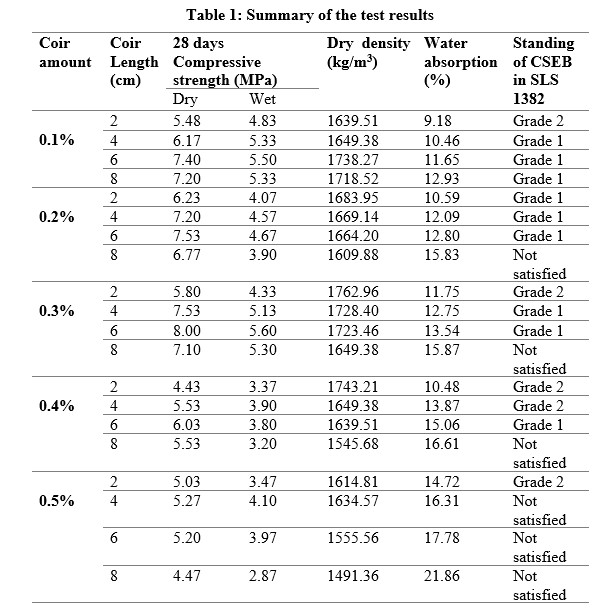

Table 1 shows the summary of the test results. Considering all the requirements, the standing of CSEB in SLS 1382 is also listed.

SLS 1382 Part 1: Specification for Compressed Stabilized Earth Blocks-Requirements defines 6.0 MPa, 4.0 MPa and 2.8 MPa as the dry compressive strength limits for Grade 1, Grade 2 and Grade 3 respectively. 2.4 MPa, 1.6 MPa and 1.2 MPa are wet compressive strength limits for Grade 1, Grade 2 and Grade 3 respectively. Water absorption should be less than 15%.

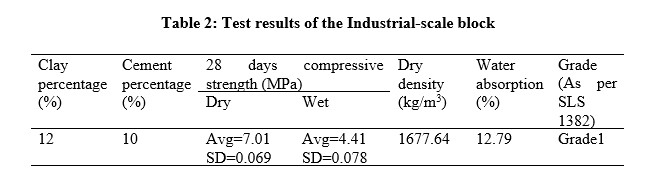

The 0.3% coir amount with a 6cm coir length was chosen as the best combination for the CSEB because it produced the highest dry and wet compressive strength while maintaining an acceptable water absorption value. The combination was then used to create an industrial-scale block (350 x 100 x 175 mm) as shown in Figure 1. Table 2 displays the 28-day test results of the industrial-scale CSEB blocks.

Figure 1: Industrial-scale block manufacturing procedure

In conclusion, Compressed Stabilized Earth Blocks offer a promising solution for sustainable and affordable construction, showcasing their potential to address environmental concerns and contribute positively to the building industry and local communities.

Eng. (Dr.) S. Nirosha Malkanthi

Eng. (Dr.) S. Nirosha Malkanthi

has earned her BSc. Eng. specializing in Civil Engineering from the University of Moratuwa, MEng. from the University of Tokyo, Japan and PhD in Civil Engineering from the University of Moratuwa. She is currently serving as a Senior Lecturer at the Department of Civil and Environmental Engineering, Faculty of Engineering, University of Ruhuna.