VIRTUAL TECHNOLOGIES IN PRODUCT DEVELOPMENT

By Eng. Priyantha SriwardeneVirtual modelling is one of the strongest tools that are used in the science and engineering today. Product designing, material engineering and process engineering all could be performed virtually in a computer before bringing them into reality. These technologies have helped to produce better performing products as well as shorten development cycles and reduce development costs. Giving visibility to the inside of the product and systems as well as flexibility to deal with what-if scenarios are the other added benefits associated with these technologies.

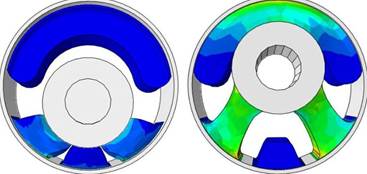

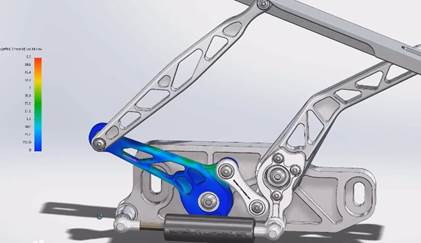

Finite Element Modelling (FEM) is one of the widely used branches in Computational Mechanics today. Its applications are varying from aircraft industry to biomedical engineering; capturing almost all engineering disciplines today. One of the nightmares of a design engineer is to capture most of the responses of their design subjected to real time application. FEM is a matured virtual simulation technology available today to help designers to understand their product designs, well before they are built for testing.

Computer Aided Design (CAD) packages are widely used today in Sri Lanka, to produce two dimensional and three-dimensional technical drawings. These packages can simulate certain behaviors of assemblies and systems. But they are not capable of giving an insight about how materials of each components strain under applied loadings. Understanding these strains will help design engineers to identify the weak regions in their designs and fix them in advance before manufacturing/building the product. This is one of the advantages you could gain with finite element simulation.

Today this technology is not widely used in Sri Lanka, by design engineers due to many reasons. One of the biggest reasons is the initial investments associated with acquiring these technologies being far higher than acquiring computer aided drafting/designing (CAD) technologies. Shortage of skilled engineers/analysts, lack of awareness, lack of management support is some of the other factors that keep this technology away from us.

This is a widely used design and analysis technology in the developed world and developing countries such as India. Using these technologies in their product development cycles have given them a competitive advantage over those who do not use them. Therefore, it has become very important for Sri Lanka to acquire these technologies to stay in the competition.

A year ago, Sri Lanka government granted Rs. 50 M to set up a finite element analysis and simulation center attached to the plastic and rubber industry as a part of their master plan for the next 20 years. This center opens to all industry segments, especially rubber and plastic products and equipped with advanced finite element analysis capabilities, computer aided design/drafting capabilities and 3D printing. The center has hired one of the experienced Engineer in Finite element studies and its technical committee is headed by academics in Sri Lanka and FE professionals working abroad.

Therefore, we invite R&D managers, engineers, research and development personnel etc, to take the maximum use of this center to support your design and analysis. This will be a great opportunity for your design teams to understand the advantages of using such tools and to get a better knowledge of using such technologies in future by them. The center also provides hands on training for personnel who are interested in developing their design and analytical skills, as well as undertake research projects together with industry personals to give them a hands on experience of using these tools.

The world is heading towards using virtual technologies in product development life cycles. Let’s make sure that Sri Lanka is not left behind.

Eng.Priyantha Sriwardene

Eng.Priyantha Sriwardene

BSc(Eng),MBA(MOT),PSE

Finite Element Analysis Expert/Expert,Analyse par éléments finis

CAMSO

2675 rue MacPherson, Magog (Québec) J1X 0E6 CANADA