Breakthrough of the Headrace Tunnel in Umaoya project; Another Landmark Victory in Sri Lankan Engineering

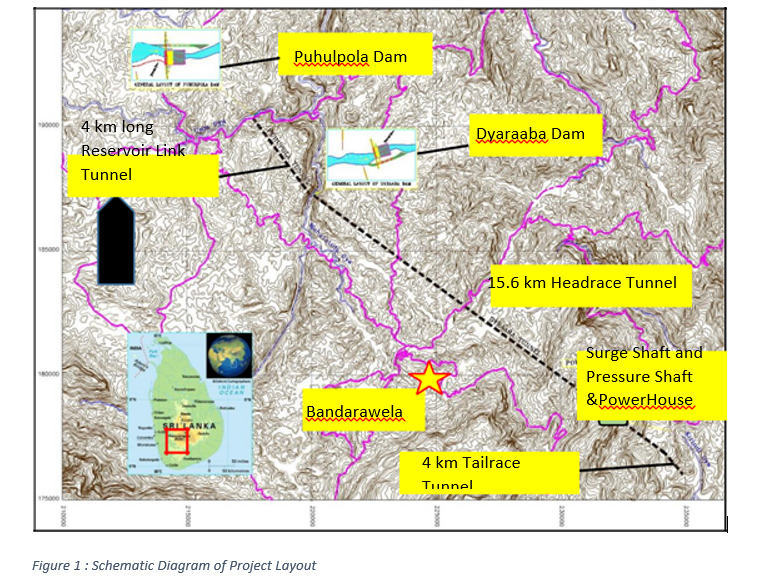

By Eng. H.W. Isuru IndunilMaking Landslide victory in Sri Lankan Underground and Mining engineering fields, the successful breakthrough of the longest deep-seated hard rock tunnel in Sri Lanka, was recorded in 2nd of October 2019. It is located in Umaoya Multipurpose Development Project, and 15.6 km long.

Umaoya Multipurpose Development Project (UOMDP) was initiated in 2009 and excavation of the Headrace Tunnel was commenced in 2013 September. The total project cost is 575 million US dollars. Project Management Unit (PMU) headed by the Project Director, appointed by the Ministry of Mahaweli Development and Environment is the project implementing agency. Central Engineering Consultancy Bureau is the Client site representative agency in addition to its premium roles in several stages of the project since Feasibility study in several decades back. The main contractor of the project was Farab Co. in Iran. The project contract type is Engineering Procument and Construction (EPC). The Poyry, Amberge Engineering-Switzerland and Mahab Ghost companies are Contractor’s consultant.

Purpose of the UOMDP are,

- Diverting of 145 MCM of water from the Mahaweli basin (crossing Mathatilla oya and Dulgolla oya) to the Walawe basin.

- Generating 120 MW (annual 231 Gwh) electricity to the national grid.

- Irrigating 5,600 hectares of new agricultural lands in Monaragala district.

- Supplying drinking water to new 5,450 families in Badulla, Etampitiya, Welimada, Bandarawela and Haputhale divisional secretary divisions.

The total project progress up to November 2019 was 93 %. The remaining sections was post excavation grouting and finishing works at HRT, transmission line to Badulla sub grid, miscellaneous works in the Powerhouse complex and etc.

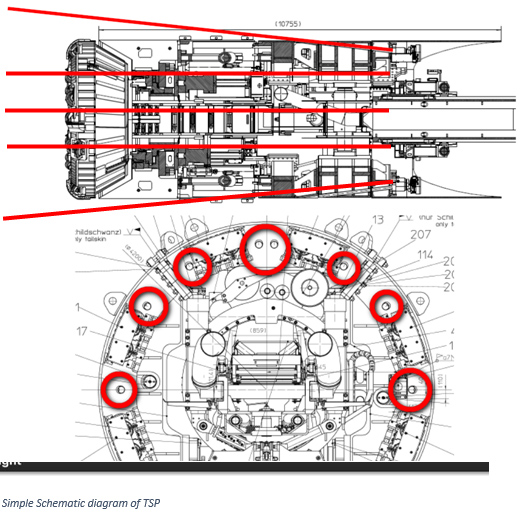

Two Double Shield Rock Tunnel Boring Machines were utilised to excavate 15.6 km long particular water conveyance tunnel. Excavation diameter was 4.3 m.

Featuring in the Umaoya project.

- First, trans basin project in Sri Lanka (Mahaweli basin to Walawe basin)

- Highest recorded water head (720 m)

- First ever mechanized tunnelling and shaft method (Tunnel Boring Machine to excavate horizontal HRT and Raise Boring Method to excavate vertical pressure shaft and Surge Shaft).

Umaoya multipurpose development project is executed as a part of the Mahaweli Accelerated Development Project. The Concept study of the project was initiated at 1910 and the first feasibility study of the project was done in 1976 by Central Engineering Consultancy Bureau (CECB). Following several amendments and revisions, the Poyry (Finland) and Mahab Ghost (Iran) joint venture has been done the Comprehensive Feasibility Study in 2006.

The project was initiated in 2009 and was expected to complete in 2018. Following several social and political distresses, the project commissioning has been extended up to 2020 October.

The Headrace Tunnel (HRT)

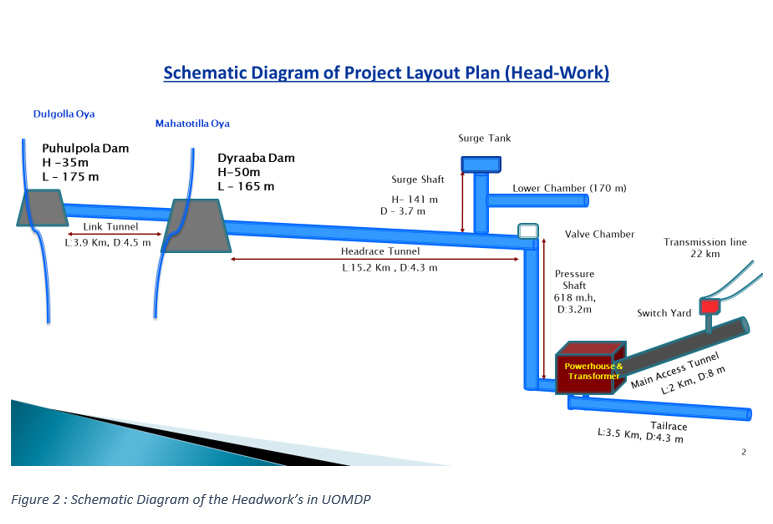

The featuring section of the project is Pressurised Water Conveyance Headrace tunnel (HRT). It can be categorised into following sections;

- The main tunnel section: it comprised 0+222.5 m to 15+249 m. that tunnel section was excavated by two Double Shield TBM machines which is called M 1684 and M 1685. The First was commenced the excavation from Upstream and continued its tunnel excavation downstream ward. The later commenced its tunnel excavation from tunnel outlet point and continued its excavation upward. Both two TBMs were completed Tunnel excavation at 4+178.4 m on October 2, 2019. That section is about 15,148 m long and conveyance water.

- HRT Intake section: it comprise 00+000 m Intake (near Dyaraaba dam) . The length of that section is 222.5 m. the Drill and Blast (Conventional method) is use to excavate that tunnel section. Water Intake structures will be accommodated in near future.

- HRT Intake and HRT Outlet adits : those two adits were created by the contractor for accessible of both TBMs and utility services. After completion of the project, the contractor will be plugged off those two adits. Intake adit is 257 m long and Outlet adit was 241 m long. Eventually, before commission of the project those adits will be plugged by concrete wall.

- Upper Pressure Tunnel (UPT); excavated by drill and blast method (total length 351 m, at 857 MASL)

- Surge Shaft: 120 m in height. Excavated by Raise Boring Machine (RBM). Diameter 3.6 m. steel lined.

- Pressure Shaft: Excavated by RBM method. 620 m in height. Diameter 3.6 m. steel lined.

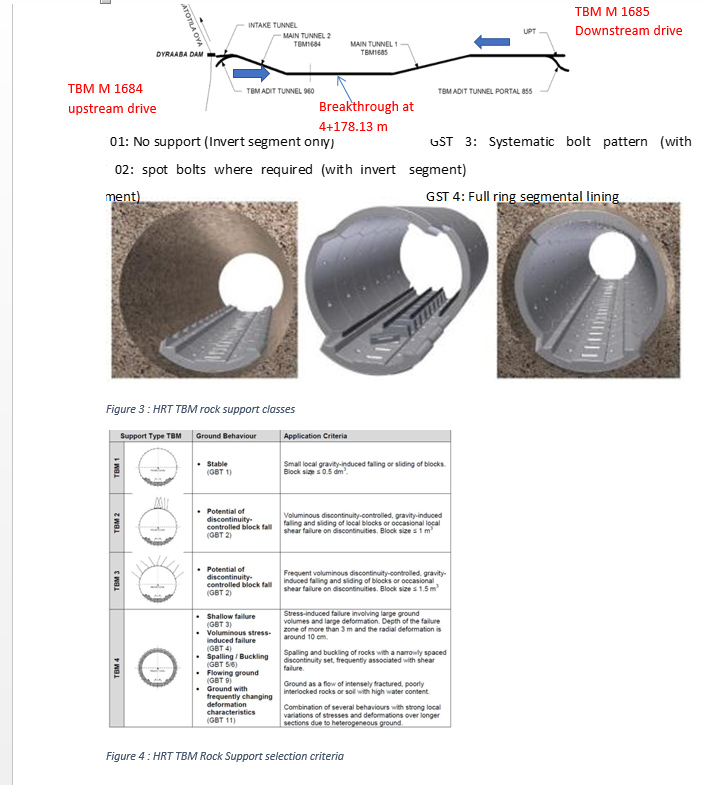

Rock Support classes

There are main four (04) Tunnels rock support classes have been executed within the entire rock excavation process as follows.

Excavation by TBMs

There are two identical Double Shield Hard rock tunnel boring machines (which are called M 1684 and M 1685) were employed by the Contractor to excavate the 15.6 long, 4.3 m diameter HRT. M 1685 machine commenced its excavation in 2013 September from the tunnel outlet (elevation 857 m MSL) heading Upstream. M 1684 started its tunnel excavation from Inlet (elevation 961 m MSL) heading downward in 2016 September. Marking the completion of successful excavation of the HRT, the breakthrough of the HRT was happened on October 2, 2019 at Ch : 4+178.13 m.

Geological Exploration of the Tunnel Ahead

Thera are three geological exploration methods were practised within the tunnel excavation period. Those were,

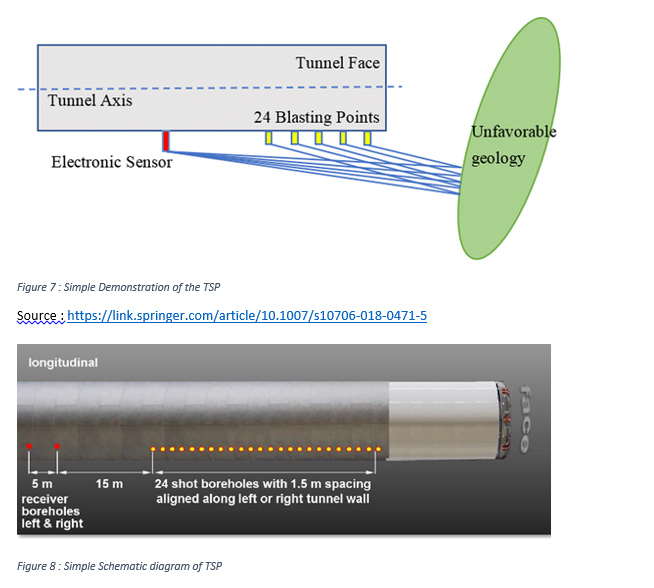

- Tunnel Seismic prediction test (TSP).

- Pre-Excavation probe drilling and grouting

- Geological mapping

This is first time used in Sri Lanka. The patent licence of that technology is governed by Amberge Engineering Co in Switzerland. A series of several successive seismic waves are originated using small explosive blasts within the rock mass behind the tunnel face. Then originated seismic waves are allowed to travel radially and it properties of the original waves are measured by installed seismic wave receivers within the rock mass. Seismic waves are travelled radially until it found geological uncertain features (eg. Rock fault, rock joint system, water available zone etc). When some uncertain feature, Seismic waves would be reflected or refraction. Then properties of the reflected waves are measured using same seismic wave receivers. And then using several software a 3D model can be created. Then rock properties, wave properties and hereinafter the several anomalies can be developed on probability of water availability ahead of the tunnel face.

This is a conventional and long-time practised method. At a certain chainage, excavation was temporary was stopped and pre excavation probe drilling commenced. There are 30 probe drilling locations are in the perimeter of the Cutterhead in each TBM body. Required probe drilling locations are determined by the site engineer and the geologist following their past water available data, prevailing geological condition and technical knowledge. Typical probe drilling lengths were 24 m, 36 m or 56 m. All observations, washing water properties and probe rod penetration details are recorded by the site geologist and thereinafter it can be predicted the water availability, rock strength and other geological variations and features ahead of the tunnel face.

By synchronizing TSP and pre excavation probe drilling details, it can be formulated proper geological 3D model on the ahead of the face. And the Contractor gets sufficient times and understanding to plan the future excavation and mitigation plans.

Dewatering Plan

Special Dewatering plan was executed by the contractor within entire excavation period as capacity in 650 liters per second in Intake drive (water which collected in Outlet drive was flown out by the gravity, hence no dewatering required). Special high capacity dewatering pumps, high durable pipe lines and electric panel boards were imported by the contractor.

Rock Mass Grouting

Completion of the Rock Mass grouting and Post Grouting: special Rock Mass grouting required sections are selected along the HRT trace and RMG will be conducted to improvement of the tunnel condition.

Conclusion

The Project Management Unit expects the commission of the project in late of 2020. After that 231 Gwh electricity will be added to the National grid to fulfil the electricity shortage in Southern and South Eastern sections in Sri Lanka. Addition to that new 5,600 hectares of agricultural land in Monaragala district will be irrigated. Mahaweli Authority of Sri Lanka and Ceylon Electricity Board will be governed the project as clients.

Eng. H.W. Isuru Indunil

Eng. H.W. Isuru Indunil

Central Engineering Consultancy Bureau (CECB)