Smart Polymers in Biomedical

BY Eng. Janitha Jeewantha

After the Industrial Revolution began in Europe around 1760, manufacturing processors rapidly changed with innovations in technology. As a result, humanity passed from the bronze and iron ages and then entered the polymer age. Since then, polymeric materials have dominated various products that are essential for our day-to-day life. Researchers have identified interesting behaviour in some polymeric materials which they named the “elastic memory” or “memory effect” and explained these through the “crystalline clutch mechanism”. Nowadays, these smart materials are called shape memory polymers (SMPs).

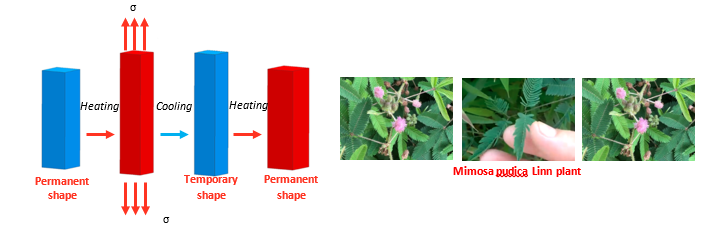

SMPs can recover their original shape upon external stimuli such as temperature, light, electricity, water, pH and magnetism, among others. This phenomenon is called the shape memory effect (SME), which is caused by entropy change because of rapid molecular motion in the polymer net points and the switching segments. Similar kinds of behaviours can be identified in nature, and the best example is the Mimosa pudica Linn plant (Nidikumba).

Figure 1: Stimuli-responsive polymer and plant

SMPs are popular owing to their manufacturability, high strain/shape recovery, tailorable glass transition temperature, low density, biocompatibility, biodegradability. However, SMPs have been hardly seen in load-bearing applications due to their weak mechanical properties. Because of this, SMPs are often reinforced with fibres such as carbon, glass, and basalt to improve their strength. On the other hand, additives enhance mechanical strength and SMP functional properties such as thermal conductivity, and electrical conductivity. These additives can range from the micro-scale to the nanoscale, but nanoparticles (NPs) have a higher surface area to volume ratio than microparticles; therefore, NPs improve shape memory and mechanical properties compared to microparticles, without sacrificing delicate SME. Carbon nanotubes (CNT), Multi-walled carbon nanotubes (MWCNT), Graphene, Titanium dioxide (TiO2), Silicon carbide (SiC), and Iron (II, III) oxide (Fe3O4) NPs were the main NPs investigated by SMP researchers.

SMP applications can be seen in space, aerospace, automotive, robotics, textile and civil structures. From the beginning, SMP researchers were interested in aerospace applications since lightweight SMP structures can avoid complex and bulky actuators mechanisms. There has been with continuous and comprehensive development in the SMP synthesis of processors, hinges, trusses, booms, antennas, optical reflectors, morphing skins, deployable radiators, and solar arrays. Due to their rapid enhancement via chemical means, the most recently synthesised SMPs were often reported to have low systemic toxicity, sterilizability, biocompatibility and natural biodegradability which has inspired biomedical researchers. Polyurethane, Polyvinyl Chloride, Acrylic and epoxy based SMPs are frequently identified in the literature; however, most SMPs are custom synthesised under a controlled environment in academic laboratories and are not freely available.

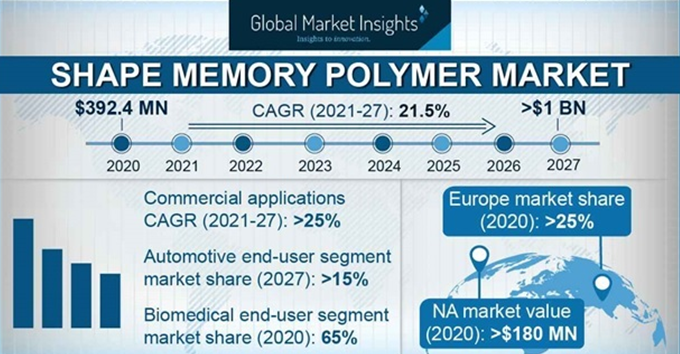

Mitsubishi Heavy Industry Japan developed the first commercially successful SMP. USA based Cornerstone Research Group Inc. and Composite Technology Development Inc. are in the race for SMP synthesis. According to Global Market Insights, in 2020 the SMP market was valued at 392.4 million USD and a 21.5% annual growth rate is expected from 2021 to 2027. Polyurethane SMPs are more popular among SMP researchers, and an over 65% market share belongs to the biomedical end-user segment. Notably, Professor Andreas Lendlein (University of Potsdam, Germany) pioneered SMP-based biomedical research and development. He has published over 700 research articles and obtained eight patents.

Figure 2: Shape memory polymer market

Source: https://www.gminsights.com/industry-analysis/shape-memory-polymer-market

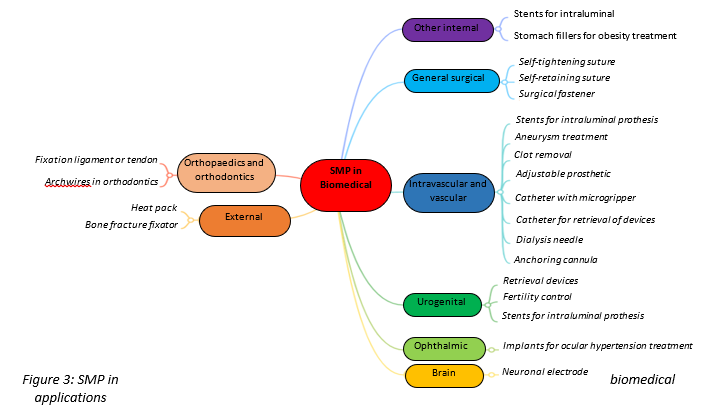

The potential for SMP biomedical applications can be seen in general surgical, intravascular and vascular, urogenital, ophthalmic orthopaedic and orthodontic. A comprehensive overview of SMP-based proposed applications is shown in Figure 3. From early 2000 to date, researchers comprehensively experimented PLLA, Chitosan, Polyurethane, and PCL based SMP stents. For example, among over 20 fabricated SMP stents, Yu PCLA stent was implanted in a dog’s esophagus during vivo analysis. Interestingly this SMP stent’s mechanical properties were effectively identical to a commercially available metallic (Ni-Ti alloy) stent. In another application, SMP ureter stents are used to keep the ureter open for abdominal tumour patients. The anchored ureter can be loaded with drugs which can be released upon stimuli. Overall, SMPs’ properties are encouraging for drug release capsules. Unlike other SMPs, most drug delivery SMP capsules are triggered by the pH of the body fluid. The diffusion coefficient drives the drug release rate to the body fluid environment. A further application is for controlling obesity, a significant burden to health care systems. SMP researchers have proposed controlling this chronic disease through SMP capsules. The foam capsule takes volume inside the stomach; thus, limits the amount of food which can enter it at a time. For capsule positioning and removal, endoscopic tools are being used. This minimally invasive approach combined with high-tech casting, 3D/4D printing, and electrospinning fabricating techniques allow the design of bone reconstruction parts at a low cost. Thiol-ene SMPs hold programmed shapes for a prolonged period and show great potential in repairing bone defects. Also, these materials are good candidates for dental applications as the SMP recovery force can be used to correct misaligned teeth with braces. After open or endoscopy surgeries, closing the wound lips without damaging the surrounding muscles is time-consuming and challenging. SMP researcher, Andreas Lendlein offered a solution by introducing self-tightening and biodegradable threads. The main aim was to apply sutures loosely and then provide external stimulus to recover the permanent shape. As an extension of this, in 2012 Huang proposed PLA/PGA copolymer based SMP staplers. These SMP staplers applied gentle force during wound closure at 48oC.

Source: https://www.tandfonline.com/doi/full/10.1586/erd.10.8

To reduce hemodynamic stress during dialysis, a deployable SMP adapter was proposed by Ortega in 2007. The obstruction of blood supply via the arteries to the brain can cause ischemic stroke, resulting in permanent disability or death. Conventionally, blood clots can be dissolved with drug treatments, but this is a time-consuming method. The developed SMP corkscrew catheter removed clots inside the vessels. Initially, a straight SMP wire was fed through the clot and triggered. Because of the stimuli, the shape changed to helical and then was pulled out with the clot. Alternatively, embolisation is a popular medical technique to block blood supply in arteries and veins in certain areas. This method can prevent internal bleeding, control and block the blood flow to the tumours and eliminate abnormal connection to veins. Foam and coil type embolisation techniques have been practised and SME are used in such procedures. However, maintaining the correct expansion pressure is crucial since high internal pressure may damage tissues and internal organs.

To treat leg ulcers, a polyurethane-based SMP pressure bandage was preliminarily investigated by Ahmad in 2019. At the same time, the Harbin Institute of Technology fabricated styrene-based forearm, finger, and wrist fracture fixators and analysed their performance through vivo experiments. SMPs showed significant potential for non-invasive biomedical applications; however, fabricated devices are limited, to the authors’ knowledge. This is mainly because of the required stiffness and strength at human body temperature (37oC). The human skin comprises lipid membranes that can be damaged with exposure to higher temperatures (>45oC) within several minutes. Most synthesised SMPs are triggered thermally, and the triggering start temperature should be higher than the body temperature to avoid self-activation. Therefore, maintaining such a narrow transition range is challenging. The University of Southern Queensland smart material team, Australia (USQ-SMRTA) has synthesised Bisphenol A based epoxy, which can be used in external orthopaedic treatments.

A rigorous performance evaluation under the appropriate biological environment is necessary before releasing the SMP product to the market. ISO 10993 Biological Evaluation of Medical Devices provides vitro guidelines including cytotoxicity, cytocompatibility, cell adhesion, genotoxicity, hemocompatibility, cell proliferation measuring protocols. Moreover, ISO 9001, ISO 13485, F1635-11 ASTM standard, EN 556-1 European standard or Food and Drug Administration (FDA) approval have been used before biomedical product release. Most SMP research outcomes could not address these requirements satisfactory; hence, limited breakthrough research outcomes are available commercially. The Acrylic- copolymer suture anchor and polyetheretherketone (PEEK) soft-tissue orthopaedic anchor have received FDA approval for permanent implementation in humans and these are commercially available.

Owing to the bioresorption properties and MRI compatibility, SMPs are ideal for many future medical applications. Novel synthesising techniques and advanced manufacturing methods will overcome the remaining challenges in the SMP biomedical field. Moreover, SMP-based both invasive and non-invasive medical devices and equipment will overcome the potential complications and drawbacks on the current procedures. We will soon see many clinical applications with these multifunctional smart materials.

Eng. Janitha Jeewantha

Eng. Janitha Jeewantha

PhD. Scholar – University of Southern Queensland. Australia

Janitha Jeewantha received his Mechanical and Manufacturing Engineering Bachelor’s degree from the University of Ruhuna Faculty of Engineering and completed a postgraduate diploma in Manufacturing Systems Engineering from the University of Moratuwa. Eng. Jeewantha gained over five years of industrial experience from Sri Lanka and then joined Sultan Qaboos University Oman. In 2019, Jeewantha accepted PhD offer from the University of Southern Queensland, Australia. Currently Jeewantha is pursuing his research under supervision of A/Professor Epaarachchi and A/Professor Islam. Jeewantha’s major research area is the advanced manufacturing and characterising of smart composite materials for biomedical orthopaedic treatments. He is also a member of the Institution of Engineers Sri Lanka (IESL) and the American Society of Mechanical Engineers (ASME).

https://www.researchgate.net/profile/Janitha-Jeewantha