Plasma Treatment

- FOR SURFACE MODIFICATION OF TEXTILES

BY Eng. (Ms.) Madushi Hansika Medagedara

Plasma is a super-heated ionic gas which is widely reactive and is mostly being used in the textile industry to modify the surface of a substrate, deposit material on surface to impart desirable chemical properties and remove previously deposited substrates from the surface for various industrial applications. It is considered as a fourth state of matter. When energy is continuously supplied to a material it will get ionized and when enough charge is accumulated, it is referred to as “plasma” which is a hot dense electron cloud. Plasma usually contains positive ions, electrons, neutral gas atoms or molecules, UV light and excited gas atoms and molecules which are unstable structures and therefore readily reacts with any surface that it will come in contact with, thus plasma can be used for surface modifications.

Plasma can be created through thermal plasma generation that consumes a high energy and also non thermally using other energy sources such as electric fields, IR beams. As an example, when applying a DC electric field across a cathode and anode plate, this causes acceleration of electrons in the cathode and consequently increasing the collisions between atoms and electrons leading towards ionization and excitation.

Plasma can be created through thermal plasma generation that consumes a high energy and also non thermally using other energy sources such as electric fields, IR beams. As an example, when applying a DC electric field across a cathode and anode plate, this causes acceleration of electrons in the cathode and consequently increasing the collisions between atoms and electrons leading towards ionization and excitation.

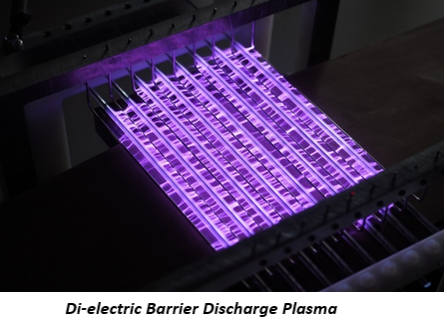

There are three distinct methods that are generally used to induce this ionization of gases. Glow discharge plasma is produced at reduced pressure however has highest uniformity and flexibility. Corona discharge plasma is produced at atmospheric pressures by applying low frequencies. Di-electric barrier plasma discharge method applies a pulsed voltage over an electrode pair.

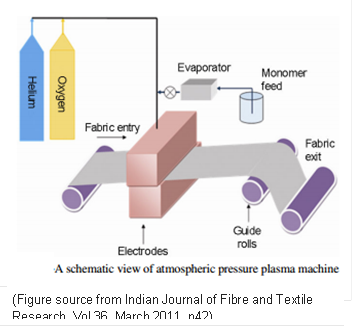

The plasma treatment process requires the optimization of several parameters including time, temperature, power as well as the distance from the plasma to the substrate, to achieve the desired surface properties. There are different types of plasma gases that are used for this purpose of surface modification, which is environmentally friendly and versatile.

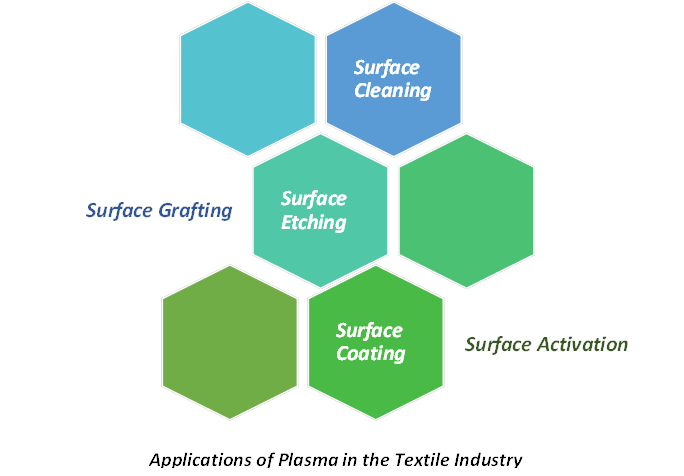

Two main plasma treatment methodologies are prevalent in the textile industry. Grafting a compound onto a fiber and surface modifications. These surface modifications include surface etching, surface activation, cross-linking, chain scission, de-crystallization, and oxidation. The plasma mediums that are generally used are Air, Fluorine, Oxygen, Helium, Argon, Carbon dioxide and water vapor. Thus, the type of treatment that can be used depends on the working medium, plasma density and the energy required.

Two main plasma treatment methodologies are prevalent in the textile industry. Grafting a compound onto a fiber and surface modifications. These surface modifications include surface etching, surface activation, cross-linking, chain scission, de-crystallization, and oxidation. The plasma mediums that are generally used are Air, Fluorine, Oxygen, Helium, Argon, Carbon dioxide and water vapor. Thus, the type of treatment that can be used depends on the working medium, plasma density and the energy required.

Oxygen plasma is used to treat cotton fabric that leads to surface erosion and consequently weight loss while increasing the Carboxyl groups present in the Cellulosic compound. Thus, imparting wettability and wicking characteristics to cotton fabric.

Similarly, Oxygen and RF Argon plasma can be used in the treatment of linen to improve the water absorbency properties of Linen fabric. For wool fabric, water vapor-based plasma treatment improves the hydrophilic properties while reducing the tendency of wool fabric to shrink. Acrylic fibers are treated with Argon, Fluorine and Hydrocarbons for water proofing, and improved hand-feel while flax fibers are treated with Oxygen and Argon to achieve fiber contractions improving the wettability characteristics.

Moreover, low temperature and low-pressure plasma is used to treat Polypropylene films (BOPP) to increase the surface energy, impart surface roughness while Nylon fabrics are treated with low temperature CF4 plasma to improve air resistance, and water repellency. A cool hand feel can also be achieved from plasma treatment of textiles because of air entrapment between the yarns.

However, there are several technical challenges and limitations of using plasma treatment. It requires a vacuum which causes complications for continuous processes, which are difficult o be carried out in a vacuum environment. Treatment of thin layers without modifying bulk properties is another technical challenge that plasma treatment poses. Furthermore, plasma treatment requires a large number of samples, high investment costs, adaptation mechanisms, technical skill to determine treatment parameters and dosage requirements which requires investment of capital expenditure, time and energy.

Nevertheless, when outlying the environmental factors, the versatility of the production methods and the properties that can be achieved, the benefits surpass the challenges by far, especially when considering the consumption of textile, the textile manufacturing intensity and capacity. Therefore, investment in such sustainable measures can reduce the carbon footprint while delivering a better, lighter, and more environmentally friendly alternative to traditional surface modification methods of textiles.

References & Image Sources

https://www.ipr.res.in/outreach/documents/modelgdp.html

https://www.igvp.uni-stuttgart.de/en/research/plasma-technology/sources/barrier/

https://www.intechopen.com/chapters/17644

Eng. (Ms.) Madushi Hansika Medagedara

Eng. (Ms.) Madushi Hansika Medagedara

Eng. (Ms.) Madushi Hansika Medagedara graduated with B.Sc. Eng. (Hons) in Textile & Apparel Engineering (Specialized in Technical Textiles) from the University of Moratuwa. She is currently employed as a Technology Entrepreneur in the Open Innovations HUB, Twinery, MAS Innovations Pvt Ltd. She is a Member of Institution of Engineers Sri Lanka (IESL) and a member of the Sri Lanka Association for the Advancement of Science (SLAAS).