LEAN CONSTRUCTION – A SERIES OF ARTICLES

EPISODE 02 – LEADING ORGANIZATIONS IN LEAN CONSTRUCTION SECTOR

BY ENG. KOKILA ARANDARA

The term “Lean Construction” was explained and elaborated in the previous (the first) episode while taking different definitions and expressions of several authors and philosophers. If one of them is re-stated, as per Abdelhamid et al. (2008), Lean construction is a combination of operational research and practical development in design and construction with an adaptation of lean manufacturing principles practices to the end-to-end design and construction process. The last discussion was ended with the introduction of three Lean Construction companies namely Vinci (France), Bechtel (USA), CRCC (China).

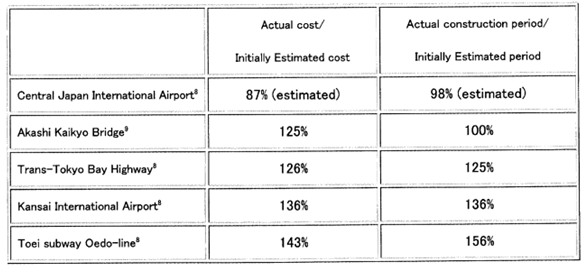

This second episode starts and continues with a few more examples for those who practice lean construction concepts. Lindner Group (Germany) is a leading company for building envelope, interior fit-out, and insulation in Germany. The New Stock Exchange in Zurich is a showcase for Lindner on how the Lean Construction Management concept brings more structure to complex construction projects through well-considered planning. The website of Lindner emphasizes that applying Lean Construction Management on site, Lindner has had a remarkable effect on the way they work: it has optimized their installation procedures, improved the quality of their workmanship, and given them greater certainty for their schedules and budgets. Further, it states that as a result of practicing Lean Construction Concepts, Lindner ensures that their plans are always made in cooperation with the project’s various stakeholders. Lindner shows that they follow Lean Rules and Principles (will be explained in the next episode) and accordingly, when construction starts, Lindner makes sure that the project’s individual tasks are dealt with on time, and that they fulfil the client’s trade, budget and time expectations. Also, to regularly monitor the project’s overall progress, Lindner always starts weeks with a review of work to date, and Lindner is passionate to hold morning stand-up meetings daily. Through value-driven processes and efficient communication, Lindner creates the optimal surroundings for the site team to focus on their work and achieve outstanding results (lindner-group.com, 2021). Marina Technology and Construction Pte. Ltd (Singapore) is a reputed waterfront contractor and committed to unlocking business value for their esteemed clients in Singapore. This company has aligned to Lean Construction practices and it is validated by a report presented jointly by Workforce Singapore, McKinsey & Company, and Building & Construction Authority (BCA), Singapore on Lean Construction and Job Redesign Guide in 2019. That particular report declares that Marina Technology and Construction Pte. Ltd has achieved savings and improvements as a result of the Lean Construction practices that they are aligned with. For example, the said report highlights that in the Pilling work point of view, time taken to set up guides and in-situ splicing were reduced by achieved estimated cost savings of around 50% and 80% respectively, target to increase productivity was exceeded by 40%, consistently achieving 1.4 piles a day, and estimated cost savings of around $ 420,000 a year was achieved. Southland Industries (New Zealand) is a company that is related to the construction sector and dealing with Architectural and Structural Metals Manufacturing while representing upstream of the construction supply chain. As per a blog on “How leaders are changing the construction industry” written by an Engineering Professional and a Lean Leader of Southland Industries, they have taken several initiatives and gains followed by the Lean Construction approach. The aforementioned blog states that one key initiative is implementing the Last Planner System, which helps them to keep moving the project forward. Another key strategy for reducing waste is offsite prefabrication. By prefabricating large sections of duct, piping or even a combination of systems/trades, in a controlled shop environment, not only material waste is reduced, but also value is added by increasing the quality of the final product. Further, the same blog indicates that an offsite shop that was started as a Lean initiative has resulted in a much safer environment for workers and lead to quicker fabrication than if the same process were to take place in the field (leanconstructionblog.com, 2021). In Australia, CPB Contractors is one of the largest construction companies, and CPB (Australia) practices and aligns with Lean construction concepts. Accordingly, the tender and the project teams of CPB are equipped with more levers to innovate, mitigate risk, add value and drive performance (CBP-Contractors-Annual-Report, 2017). At last but not least, Central Japan International Airport Company (CJIAC) (Japan) is the operating body of the Central Japan International Airport in Japan, and CJIAC was designated to construct and manage the airport efficiently and established as the private sector in 1998 by the national government. The main shareholders were the Japanese national government, prefectural governments, municipal governments, and private companies that in a way having different shareholding ratios while having 39.9% of share to the Japanese National government. The CEO of CJIAC to manage the massive project of design and construction of Central Japan International Airport particularly was a former member of the board of directors of Toyota Motor Corporation as result followed by political and business establishments to activate the private sector as much as possible by applying Toyota's lean management system to the airport project (Taguchi, 2004). As per Taguchi (2004), CJIAC had applied the lean concept to a large and complex construction project for the first time in Japan. Table 01 shows two KPIs (Key Performance Indicators) related to the project of construction of Central Japan International Airport while comparing the same KPIs applicable to another four large-scale projects that happened in the same decade in Japan.

Table 01: Comparison of large projects’ cost and schedules in Japan (Taguchi, 2004)

On the other hand, there are different leading Institutions and Organizations that produce several training and development programs appropriate to Lean Construction throughout the world. Those entities play a dedicated role to enhance the construction industry as a whole particularly, with the member construction companies who believe in and practice Lean Construction concepts. A few of the leading organizations/institutions are explained below.

In Japan, HIRAYAMA Co., Ltd. is a leading organization and it is a Tokyo Stock Exchange-listed company. Hirayama delivers several Lean Construction Training Programs for both locals and international professionals while aiming to improve work efficiency, reduce disasters, and introduce the latest technology (jp-expert.com, 2021). Also, Lean Construction Australia and New Zealand (ANZ) is the pre-eminent organization promoting and supporting higher levels of sustainable performance of the construction sectors in Australia and New Zealand. Lean Construction ANZ (LCANZ) is managed by a Board of Directors and Regional Councils comprising lean leaders from the private, public, and education sectors. The construction sector in Australia and New Zealand exhibits a high incidence of project cost and time overruns, business insolvencies, and stagnant productivity. LCANZ believes that applying lean construction principles offers a way to enhance project success and increase the likelihood that projects will be more collaborative, have less wasted effort and deliver appreciable customer value (www.leanconstructionanz.org, 2021). In Singapore, it can be seen that there is a government intervention also to organize and deliver training programs in Lean Construction. The Building & Construction Authority of Singapore (BCAS) is an organization of Singapore government and that provides dedicated training programs in Lean Construction (www.bcaa.edu.sg, 2021). The Xi’ An Jiaotong Liverpool University in China plays a remarkable role to enhance the knowledge and engagement of construction professionals in terms of Lean Construction. The Department of Civil Engineering, carried out a research project called “Sz215” for three months to observe the construction process and the application of lean techniques (www.xjtlu.edu.cn, 2021). The Lean Construction Institute (LCI), USA is a member-based organization whose mission is to transform the fragmented design and construction industry through lean thinking, tools, and technology. integrate their very isolated industries and create extraordinary value for all project stakeholders. LCI’s plans include: developing research products to help companies implement lean production more effectively; learning programs to help answer the “why” and “how” of lean implementation; and unique national and regional activities to promote lean learning and networking across the industry. Delta Partners, France is also a leading organization that produces Lean Construction Training Programs dedicated to construction industry professionals in France (www.delta-partners.fr, 2021). Particularly, the International Group for Lean Construction (IGLC) that was founded in 1993 is an International Network of researchers from practice and academia in architecture, engineering, and construction (AEC) who feel that the practice, education, and research of the AEC industry have to be radically renewed in order to respond to the global challenges ahead (www.iglc.net, 2021).

The next episode would bring some key lean theories and concepts that are practiced in the Lean Construction sector.

References:

CBP-Contractors-Annual-Report, C. (2017). CPB Contractors-Annual Report;. Australia: CPB Contractors.

fletchergroupve.com. (2021, 09 25). fletchergroupve.com. Retrieved from https://fletchergroupve.com/: https://fletchergroupve.com/

jp-expert.com. (2021, 9 20). Retrieved from jp-expert.com: https://jp-expert.com/company-2/

jp-expert.com. (2021, 09 20). jp-expert.com. Retrieved from https://jp-expert.com: https://jp-expert.com/tour/ci12/

leanconstructionblog.com. (2021, 09 26). leanconstructionblog.com. Retrieved from leanconstructionblog.com: https://leanconstructionblog.com/How-Lean-Leaders-are-Changing-the-Construction-Industry.html

lindner-group.com. (2021, 09 20). lindner-group.com. Retrieved from https://www.lindner-group.com/: https://www.lindner-group.com/en/news/detail/lean-construction-in-practice-5503/

Taguchi, H. (2004). Application of Lean Enterprise Concept to Construction Firms in Japan. Tokyo: Massachusetts Institute of Technology.

www.bcaa.edu.sg. (2021, 9 20). https://www.bcaa.edu.sg/. Retrieved from https://www.bcaa.edu.sg/: https://www.bcaa.edu.sg/docs/librariesprovider2/academic-programmes/specialist-diploma/79011_031018_0001c66e30c232306ef1b0a0ff0200a28c6c.pdf?sfvrsn=986f6109_2

www.delta-partners.fr. (2021, 9 20). www.delta-partners.fr. Retrieved from www.delta-partners.fr: https://www.delta-partners.fr/contacts.html

www.iglc.net. (2021, 9 20). www.iglc.net. Retrieved from www.iglc.net: https://iglc.net/

www.leanconstructionanz.org. (2021, 9 20). www.leanconstructionanz.org. Retrieved from www.leanconstructionanz.org: https://www.leanconstructionanz.org/about/

www.xjtlu.edu.cn. (2021, 9 20). www.xjtlu.edu.cn. Retrieved from www.xjtlu.edu.cn: https://www.xjtlu.edu.cn/en/news/2020/12/cen-lean-construction-management

Eng. Kokila Arandara

Eng. Kokila Arandara

Lead-Lean Construction Practitioner in Sri Lanka,

Founding Director,

Lean & Green Solutions (Pvt) Ltd.