Structural Failures: Understanding the Root Cause

By Eng. (Prof.) Chaminda S. Bandara

This article has been prepared based on the Eng. (Prof.) E. O. E. Pereira Memorial Oration that took place at the Wimalasurendra Auditorium, Institution of Engineers Sri Lanka, Colombo on 13th September 2024, organized by the Civil Engineering Sectional Committee of the Institution of Engineers Sri Lanka.

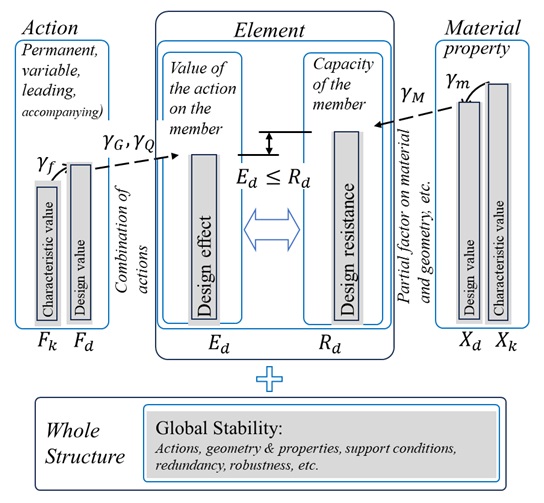

Structural Integrity of structures relies on the properties of materials used, the geometry of structural elements & the whole structure, and the actions to which the structure is subjected. In today’s structural designs, all these different aspects are taken into consideration. The element designs are carried out by comparing the element (member) level design effect with the element (member) level design resistance obtained from factored actions on the member and the factored resistance of the member, respectively. The global stability of the whole structure is verified by considering the combined actions, the geometry of the whole structure and its properties, support conditions, redundancy and robustness, etc. Further, the economic, environmental, and sustainability factors are also taken into account. Understanding the root causes of failures of failed structures has immensely helped in the development of design codes and standards. The lessons learned from past experience have contributed to today’s engineering marvels. Examples of two structural failures; 1) the Tacoma Narrows Bridge (1940) and, 2) the Silver Bridge (1928-1967) - that led to a revolution in steel bridge engineering are discussed in this article.

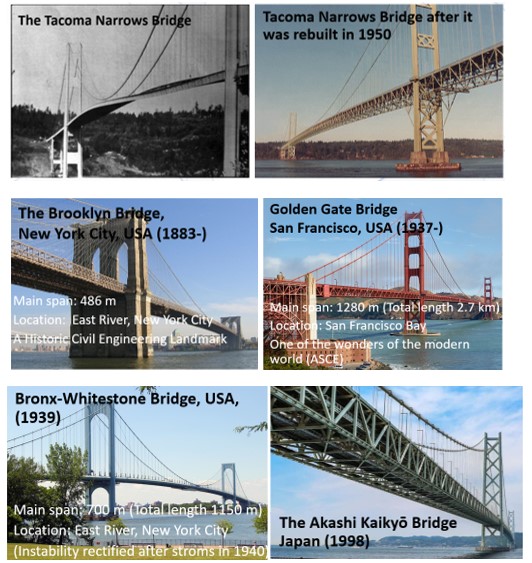

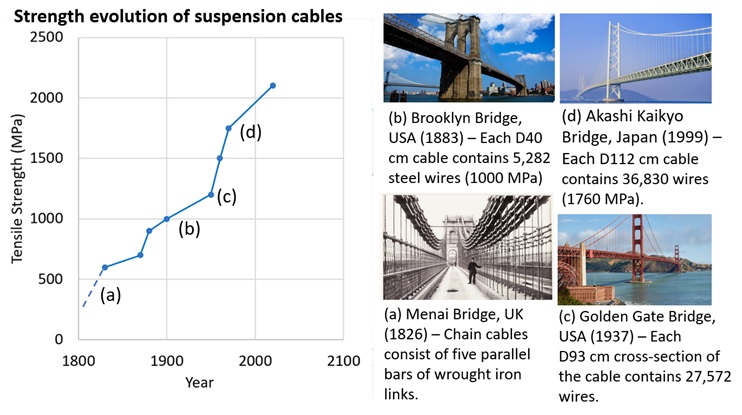

The Tacoma Narrows Bridge was a steel girder suspension bridge. The main suspension span of the bridge was 854 m and its total length was 1810 m. The revolutionary girder bridge deck design was slender and economical compared with deep steel truss decks used for long-span bridges at the time (i.e. the Brooklyn Bridge (USA) (wrought iron bridge) with a main span of 486 m built in 1886 and the Golden Gate Bridge (USA) (steel bridge) with a main span of 1280 m built in 1937 are two examples of girder suspension bridges). It has been reported that in the design of the Tacoma Narrows bridge, 2.4 m deep girders replaced 7.6 m deep trusses designed earlier. The static wind design of the Tacoma Narrows bridge was based on the theory of elastic distribution which was an extended version of the deflection theory devised by the Austrian engineer Josef Melan. The design expected that the stiffness of the main cables (via the suspenders) would absorb up to one-half of the static wind pressure and the wind load would be transmitted to the towers and anchorages. However, the bridge collapsed on 07th November 1940 just 4 months after it was opened to traffic. The failure of the bridge was caused by heavy wind-induced flutter instability and the divergent motion of the bridge deck due to the wind action on the girders. This failure led to numerous studies at the structure level and the element (structural member) level. However, material-level failure has not been widely discussed because the material was not the main factor in this type of failure. A few other girder suspension bridges built in the 1930s such as the Bronx-Whitestone Bridge (the main span is 700 m) in the USA in 1939 also had wind instability issues.

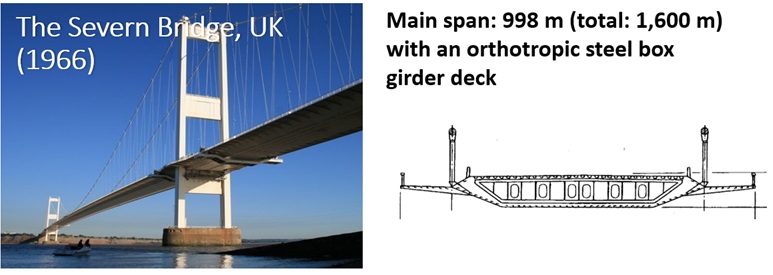

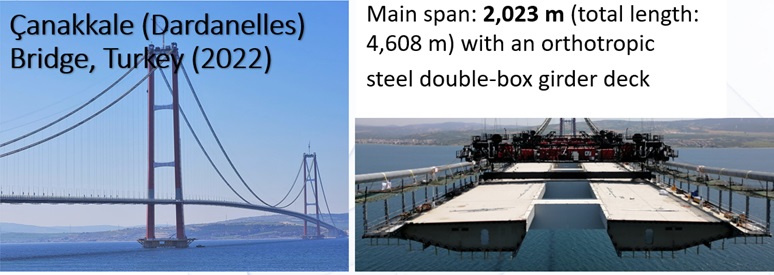

After the Tacoma bridge failure, two main trends in bridge engineering can be observed: 1) returning to deep truss deck type bridges, and 2) studying the wind behaviour and aerodynamic bridge deck profiles. A few examples of the first are, the reconstructed Tacoma Narrows bridge with a truss deck in 1950, the Mackinac Bridge (USA) built in 1957, and the Akashi Kaikyō Bridge (Japan) built in 1998 (Akashi Kaikyō Bridge has the world's 2nd longest main suspension span of 1991 m). The first example for the second observation is the Severn Bridge built in the UK in 1966 with a slender main span of 998 m, with an aerodynamic bridge deck cross-section profile through wind tunnel testing. It is important to note that the use of wind aerodynamics instead of static analysis, taking into account the influence of wind–rain combination, wind tunnel testing & numerical wind simulations, and the use of clamps and dampers were all developed due to the failure of the Tacoma Narrows bridge.

The contribution of the development of materials and the improved know-how of material-level failures towards the development of steel bridges was immense. The lessons learned from the failure of the Silver Bridge in 1967 were significant for the material-level improvements.

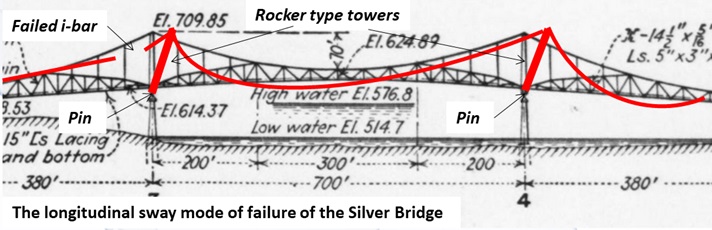

The Silver Bridge, a suspension bridge made of wrought iron with a main span of 210 m and a total length of 681 m opened to traffic on 30th May 1928. It collapsed on 15th December 1967 after 39 years of service. The root causes for this failure are complex and linked to both; 1) the element and structure level issues such as the I-bar chains, rocker towers, and structural redundancy, and 2) material level issues such as corrosion and fatigue. The investigations showed that the fatigue fracture of an I-bar link caused the collapse of the entire bridge structure. Wrought iron I-bars were used for suspension main chains of bridges in the 1800s. Material level failure causes such as fatigue were not adequately considered in structural designs. The other observation is negligence on the redundancy aspects. After this structural failure, the design aspects of overall stability and robustness requirements improved, and, design codes and standards addressing fatigue, corrosion, and other material level failures, and strategies for regular bridge inspections, health monitoring and damage assessment of bridges, etc came into regular practice.

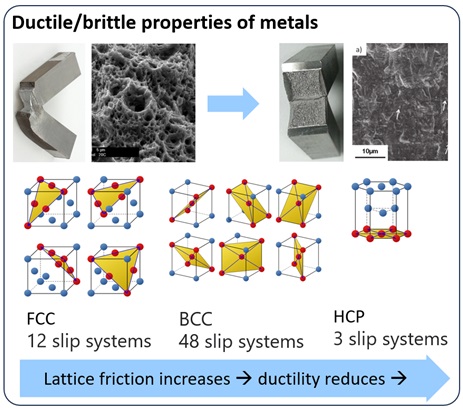

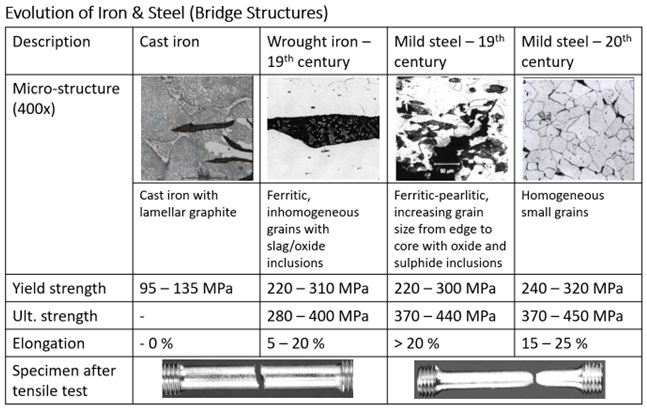

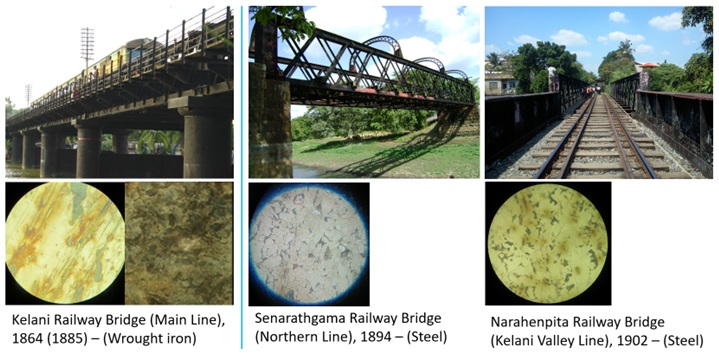

Common material-level failures of metals used in bridge structures are ductile/brittle fracture, fatigue, and corrosion. In the materials level analysis, it is important to understand the behaviour of the atomic lattice when a structural element is subjected to stresses, temperature variations, etc. The basic lattice of metals is face-centered cubic (FCC), body-centered cubic (BCC), or hexagonal close pack (HCP), and the number of slip systems in these lattices is different. The ductility of materials depends on the resistance of the slip systems. Deformation is the cumulative effect of atomic slip. FCC with 12 slip systems is ductile, BCC with 48 slip systems is less ductile than FCC due to the interlocking nature of atoms when there are too many slip systems, and HCP is brittle as it has only 3 slip systems. At low temperatures, as the energy level is low, the lattice friction is high which makes metals brittle. The addition of atoms into the metallic lattice such as carbon, and impurities in metals increases slip resistance as they disturb the atomic slip. The ductility level of iron and steel having FCC lattice changes due to impurities, carbon, and other alloying elements. It is known that the wrought iron used in bridge structures in the 17th – 18th centuries is more brittle than the comparatively pure steel used from the 18th century onwards. This brittle behaviour of wrought iron is the cause of some of the brittle-like fractures that occurred in old iron bridge structures.

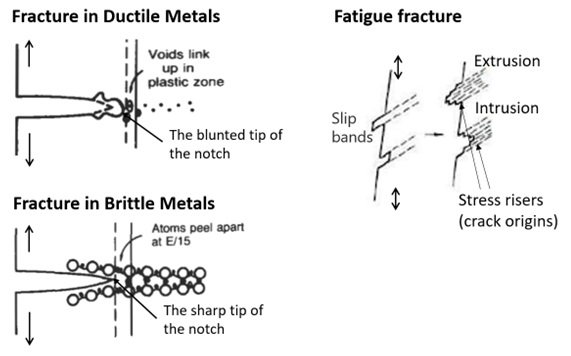

Fracture of structural elements starts from hot spots such as sharp notches (i.e., surface or internal defects, joints with bolt holes, unsmooth welds, corrosion pits, etc) where the stress is greater than the yield strength. In ductile metals under high stresses, the tip of the notch gets blunted as the atomic slip is easy. Therefore, the fracture happens by ductile tearing. However, in brittle metals, as the atomic slip is limited, blunting does not occur. Therefore, the stress and the related energy at sharp crack tips are very high and adequate to break atomic bonds leading to crack propagation and fast fracture. Fatigue fracture, the other common fracture seen in bridge structures, takes place due to cyclic loading caused by moving vehicles. Even in ductile steel, fatigue fracture is brittle, and happens due to the initiation and the propagation of a fatigue crack. The reason for this is that the cumulative atomic level slips (i.e. slip bands) that form extrusions or intrusions make tiny crack-like notches where the stress concentration and related energy are adequate to break atomic bonds.

The improvement of steel played a significant role in the development of steel bridges. Until the 18th century, wrought iron was the main material used for bridge structures and suspension chains. Mild steel is the next common material observed in bridges built in the 19th and 20th centuries. The same metals can be seen in old bridges in Sri Lanka. Engineers started using steel with a yield strength above 300 MPa as structural steel and steel with a yield strength above 1000 MPa for suspension cables in bridges in the 19th century. It is well known that today we have different types of steels (and alloys) with different strength grades and properties for different purposes.

The capability of engineers to accurately predict the structural behaviour for various actions (loading), the effective geometry of the structural members/ whole structure, the know-how about different material, element & structure level failures, and the improved materials (steels and alloys) are the main reasons for the successful long-span steel bridge designs at present. Nowadays, it is rare to see deep and heavy steel truss decks in long-span suspension bridges. All these improvements can be seen in the Canakkale Bridge in Turkey that opened in 2022 which has been designed with an efficient aerodynamically stable deck made of high-strength steel and broke the record of the world’s longest suspension main span, exceeding 2 km (2023 m).

In the future, it is extremely important to take into account the economy, efficiency, and sustainability aspects of bridges. The two main areas that require attention are the use of; 1) existing bridges as long as possible which requires well-planned strategies, rules & regulations towards regular inspection, health monitoring, maintenance, repair & retrofitting of bridge structures, and 2) economical and efficient designs for new bridges which require innovative designs, advanced materials, and strategies for efficient construction and maintenance.

Eng. (Prof.) Chaminda S. Bandara

Eng. (Prof.) Chaminda S. Bandara

Department of Civil Engineering

Faculty of Engineering

University of Peradeniya