Mechatronics - A Marriage of Mechanics and Electronics

By Prof. Clarence W. De Silva"A narrative of how I accidently embarked in the field of Mechatronics while working as an engineer in Sri Lanka in the early 1970s."

Professor Clarence W. de Silva is a Professor of Mechanical Engineering at the University of British Columbia, and has occupied several research chairs including NSEC-BC Packers Chair, Mobil Endowed Chair, and the Senior Canada Research Chair in Mechatronics and Industrial Automation. He is an engineering graduate of The University of Peradeniya, and a Fellow of ASME, IEEE, Canadian Academy of Engineering, and the Royal Society of Canada. He has received many awards including the Paynter Outstanding Investigator Award and the Takahashi Education Award of ASME Dynamic Systems and Control Division; Killam Research Prize; and Outstanding Engineering Educator Award of IEEE Canada and has served as Editor/Associate Editor of 14 journals including ASME and IEEE transactions; and is the Editor-in-Chief of the International Journal of Control and Intelligent Systems. Having received PhD degrees from Massachusetts Institute of Technology and University of Cambridge, the higher doctorate (ScD) from University of Cambridge, and an Honorary DEng from the University of Waterloo, he has authored 25 books and 580 research papers and articles, half of which are in journals, and is here to share his knowledge upon the establishment of the course of Mechatronics in Sri Lanka, while sharing his life experiences as an inspiration to aspiring young scientists and engineers.

Professor Clarence W. de Silva is a Professor of Mechanical Engineering at the University of British Columbia, and has occupied several research chairs including NSEC-BC Packers Chair, Mobil Endowed Chair, and the Senior Canada Research Chair in Mechatronics and Industrial Automation. He is an engineering graduate of The University of Peradeniya, and a Fellow of ASME, IEEE, Canadian Academy of Engineering, and the Royal Society of Canada. He has received many awards including the Paynter Outstanding Investigator Award and the Takahashi Education Award of ASME Dynamic Systems and Control Division; Killam Research Prize; and Outstanding Engineering Educator Award of IEEE Canada and has served as Editor/Associate Editor of 14 journals including ASME and IEEE transactions; and is the Editor-in-Chief of the International Journal of Control and Intelligent Systems. Having received PhD degrees from Massachusetts Institute of Technology and University of Cambridge, the higher doctorate (ScD) from University of Cambridge, and an Honorary DEng from the University of Waterloo, he has authored 25 books and 580 research papers and articles, half of which are in journals, and is here to share his knowledge upon the establishment of the course of Mechatronics in Sri Lanka, while sharing his life experiences as an inspiration to aspiring young scientists and engineers.

Q: Dear Professor, first our readers, would love to get to know how you embarked upon this journey as an engineer.

I was an engineering student at the University of Peradeniya (then known as the University of Ceylon), in the second half of the 1960s. There we did not have access to digital computers. Then, when I was about to graduate, a main frame computer was installed at the faculty of engineering. It was enormous in size, and a large air conditioned room was needed for its installation, unlike today's desk-top personal computers (PCs), that have more functionality, capability, and speed, and are far smaller and cheaper! Anyhow, first we had to learn a programming language, typically FORTRAN, before we could use the computer. Even after that, we had to "punch" decks of cards according to our program, handover it to the supervisor, and wait for many hours if not a day, to get a printout of the results.

Q: So, Professor, you have had the experience of working on one of the earliest generations of computers?

Yes, often, the "output" had errors (bugs), and the correct output came only after several iterations of correction, punching, submission, and waiting. Unlike these days, to learn a programming language, we had to use the relevant manuals or books, and these were not freely available online or in our library. The set of manuals for the computer were kept under lock and key and were carefully guarded by the supervisor. Undeterred, I purchased the booklet on Fortran Programming, written by Prof. Sam Karunaratne (who was at the State Engineering Corporation at the time), and carefully mastered it. Once I was ready to program in FORTRAN, I had already graduated and was working as an engineer in a large factory in Nawinna, Maharagama. The company did not have computers, but the chief engineer offered me a relevant project soon after I joined the factory.

Q: I believe professor, that this was the turning point of your career?

Truly Yes! Unbeknownst to me, that was my first and fortuitous exposure to rudimentary Mechatronics. I will explain this now, and its connection to computers later.

In my daily "walk through" in the factory, I noticed an alarming (hazardous) situation. The factory used about ten "buffing stations" where the workers manually held rubber parts (the factory produced items made of rubber, plastic and aluminum, among other things, in large scale) to the spinning emery wheels, at the buffing stations, and removed any minor artifacts in the parts and also polished them in the process. The whole area was full of rubber dust, and even though the buffing workers wore masks, I was sure they inhaled some of that dust daily.

Q: Hazardous and unhealthy I presume?

Indeed! I asked the chief engineer whether we could improve the situation and suggested two options, either install a good ventilation system or to redesign the buffing machines for them to be less hazardous. Fortunately, the chief engineer agreed, and told me "I will take care of the ventilation system, and you redesign the buffing machines." He said, he would assign an experienced foreman for the project, and I could acquire the needed parts from the Department of Requisition.

Q: If I may ask, were the workers supportive of this new implementation Professor?

By all means, but little did I know, the assigned foreman was a disaster, known to be lazy, and did not want to do any work, and above all, did not like to take instruction or advice from anyone. The chief engineer had just wanted me to somehow change the foreman's habits and make him at least a bit productive, I suppose (laughs). Even though I was young and somewhat naive, I resorted to some trickery. I told the foreman that I did not know much engineering, and I wanted to learn from him (even though I had a first class honors degree and topped the entire class of engineering, winning the Dr C. H. Hewavitarana prize).

Q: He must have been flattered-?

I told him that I would recommend him for a bonus, on completion of the project. During the project, I did not question his decisions, but tactfully corrected any of his errors that I noticed. So, gradually, he became a changed man and was quite friendly with me, while boasting to others that he could teach a thing or two to "these highly-paid engineers." He was correct indeed!

Q: Moving on towards Mechatronics, how was the academia prepared for this revolution in those days?

The powers who designed the engineering curriculum at our University, the likes of our beloved dean, Professor E.O.E. Pereira, had the foresight to plan for the future proactively. The first two years of the program were common to all engineering students (consisting of just Mechanical, Electrical, and Civil engineering students, at the time), and hence fortunately I learned electrical engineering and electronics as a result, even though my specialization in the final two years was mechanical engineering. So, as my main practical project (after the final year project at the university, which is another story), I embarked on Mechatronics.

Q: So, all in all there must have been a considerable amount of self-taught areas as well-?

Oh yes, I refreshed my electrical engineering knowledge and learned how to select electric motors (particularly induction motors), to properly match a load (which is the object that is rotated by the motor). I learned the types of control that were available for induction motors. I brushed up my knowledge on the analysis of rotating bodies and particularly how to determine the torque versus speed curve of a load (through Mechanics of Machines that I learned in the university). Most of this study was done in the evenings, outside the normal working hours (the chief engineer had given me a nice house within the factory premises, free of rent. It had many spare rooms, as I was single at the time. However, since the factory operated in three shifts, the foremen would come knocking on my door when a machine malfunctioned. Of course, I did not know how to fix the machines. So, I learned the trade from the foremen, and also told the workers that in case of trouble they should first go to the foremen. Since all the foremen were friendly with me, another headache was avoided, and I managed to get some sleep. (laughs)

Q: Professor, so how was this new knowledge applied to find a solution to the dust issue, could you please explain to us in layman's terms?

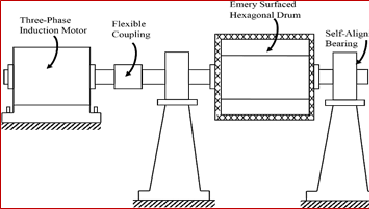

First I designed a hexagonal drum of appropriate capacity (doing some guesswork, based on the number parts that were buffed in five of the existing stations in one hour and assuming that the new buffing machine would run for an hour to complete that batch) with the hope of gluing suitable emery paper in the interior as in the image below. Then I estimated, with the help of the foremen, the weight of the drum with a full load of rubber parts. Finally, I calculated the moment of inertia of the loaded drum about its axis of rotation, and also determined the torque versus speed curve for it. That was the easy part.

Next, a suitable shaft and bearings for the drum had to be selected. The support structure (the stand) had to be designed, and a suitable induction motor had to be chosen. With the eager help (and rigorous advice) from the foremen, much of the design was completed except the selection of the motor. The motor selection was particularly difficult for several reasons. We had to depend on a few available motors (about four, as I recall). No data sheets, manuals, or even a standard torque versus speed curve were available (unlike today, when we can simply obtain all this information online). Motor control involved simple start and stop, and at best, two-speed, "pole-changing" control. Unlike today, no sophisticated, variable speed, frequency control and field vector (magnetic flux vector) control were available then. In any case, the motor has to operate in its stable region, and the corresponding torque depends on the "slip," which in turn depends on the motor speed.

Next, a suitable shaft and bearings for the drum had to be selected. The support structure (the stand) had to be designed, and a suitable induction motor had to be chosen. With the eager help (and rigorous advice) from the foremen, much of the design was completed except the selection of the motor. The motor selection was particularly difficult for several reasons. We had to depend on a few available motors (about four, as I recall). No data sheets, manuals, or even a standard torque versus speed curve were available (unlike today, when we can simply obtain all this information online). Motor control involved simple start and stop, and at best, two-speed, "pole-changing" control. Unlike today, no sophisticated, variable speed, frequency control and field vector (magnetic flux vector) control were available then. In any case, the motor has to operate in its stable region, and the corresponding torque depends on the "slip," which in turn depends on the motor speed.

I had studied the analytical formula for the steady-state speed torque characteristic of a 3-phase induction motor. I fitted all the available information of the available motors and estimated (crudely) the torque versus speed curve and the stable region of the motor. By painstakingly matching this curve with the load curve and allowing for a good factor of safety (to account for the numerous uncertainties) I selected the available best motor for the job. The fabrication, assembly, and installation were the tasks of the foremen, technicians, and other workers. My job then was primarily of supervisory nature, during that activity. Fortunately, the project was successful, the workers and the management were very happy, and the foreman received a bonus (and a gratuity from me) and retired.

Q: What exactly is this process of "Buffing" Professor?

Steam-cured latex is molded into rubber parts. After cooling, the parts are placed in the drum. The motor is started, and the exhaust system is operated. After an hour, the machine is stopped, and a vacuum system is operated to clean the interior of the drum and its contents. A masked worker removes the parts into bins. The buffed (polished) parts are sent for inspection and packing. Many years later, I heard that the company developed several such buffing machines and expanded the operation, but I was not involved in those activities as I had decided to head for the University of Toronto for graduate studies.

Q: Moving on towards, "Mechatronics" Can you give a brief introduction as to what this term means?

Yes, you may have gained a hunch of Mechatronics through my narrative above. However, the area is much more than that, and is quite sophisticated now. The term itself traces back to Yasakawa Electric Co, which was established in Kitakyushu City, Japan, in 1915. The main products of the company, in the beginning, were induction motors and their controls (drive unit). Much of the company's proliferation and global expansion took place after the World War II. The company coined the term Mechatronics by "fusing" the terms "MECHAnics and elecTRONICS," in 1969, and registered a trademark in 1972. (Note: This is the time when I was working at the factory in Sri Lanka, but the true meaning of Mechatronics emerged much later. The reader should be able to connect the dots, through the sequel).

Q: So, Professor, how would the field of "Mechatronics" be applied in a practical context?

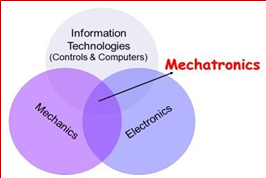

Well, the accepted definition of Mechatronics is the "Synergistic application of mechanics, electronics, control engineering, and computer science in the development of electromechanical products and systems, through integrated design." and this definition is encapsulated in the Venn diagram shown below.

Well, the accepted definition of Mechatronics is the "Synergistic application of mechanics, electronics, control engineering, and computer science in the development of electromechanical products and systems, through integrated design." and this definition is encapsulated in the Venn diagram shown below.

In this definition, the key terms are "Synergy," "Integrated Design," "Controls and Computers," and "Electromechanical Products." Now we see why our buffing machine, which is an electromechanical product with some controls (speed control) is related to electromechanical design. However, we need to explore whether we used a synergistic and integrated design approach in its development, to seriously claim a link to Mechatronics.

After I embarked in the field of Mechatronics, I expanded the established definition of Mechatronics, to include,

- "Multi-domain (multi-physics)" instead of just electromechanical products

- Integrated and "unified" approach rather than just an integrated approach

- A "systematic" approach (with a clear set of steps for the system development)

- Leading to a "unique" outcome (through design optimization).

Q: If we were to explore this in much simple terms-?

Yes, First, semantically, "integrated" and "unified" may mean the same things, but it is not so in Mechatronics. In Mechatronics, integrated means, all the physical domains (typically, electrical and mechanical, but in our extended definition, other physical domains such as fluid and thermal can also be present in a mechatronic system) are treated simultaneously (concurrently) in the modeling, analysis, design, and development of the product. Traditionally, these domains are treated separately (sequentially); for example, the mechanical and electrical parts are developed separately and then interconnected. Unified means similar (analogous) approaches are used in the developments in various domains of the product. Systematic means, very clear and established set of steps are used in the development. Unique means, the procedure leads to just one "best" design, and so, a procedure of "design optimization" is needed in Mechatronics.

Q: So, Professor, what are the basic components of a "Mechatronics System"

A typical mechatronic system consists of a mechanical skeleton, actuators, sensors, controllers, signal conditioning and modification devices, computer and digital hardware and software, interface devices, and power sources, integrated with parts that belong to other physical domains (e.g., pneumatic, hydraulic, thermal). Different types of sensing, information acquisition and transfer are involved among all these various types of components.

For example, let us consider a servo motor, which is a motor with the capability of sensory feedback for accurate generation of complex motions, consists of mechanical, electrical, and electronic components. The main mechanical components are the rotor, stator, and the bearings. The electrical components include the circuitry for the field windings and rotor windings (not in the case of permanent-magnet rotors), and circuitry for power transmission and commutation (if needed). Electronic components include those needed for sensing (e.g., optical encoder for displacement and speed sensing and tachometer for speed sensing).

Each aspect or issue itself, within a larger system, may take a multi-domain (multi-physics) character. For example, a DC servo motor alone may represent a mechatronic device, within a larger mechatronic system such as an electrical automobile or a robot, which may represent a larger mechatronic system.

Q: Would there be any more examples to illustrate this term?

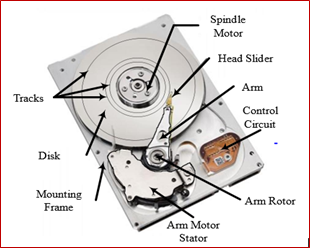

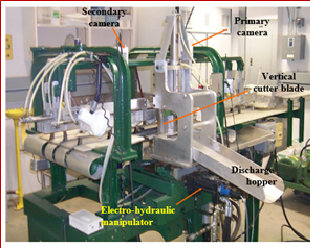

Yes, as another example, consider a hard-disk drive (HDD) unit of a computer, as shown here. Clearly, it has mechanical and electronic components. Furthermore, energy dissipation, heat generation and cooling need the consideration of fluid and thermal domains. Accordingly, it is a multi-physics device. However, strictly, it won't be a mechatronic device unless a mechatronic approach is taken in its design and development (which is not clear from the outward examination of the device). As the final example, consider the industrial machine, which has been designed and developed by us, in my laboratory at the university, for the head removal of salmon. The conveyor, driven by an AC motor, indexes the fish in an intermittent manner. The image of each fish, captured using a digital camera, is processed to determine the geometric features of the fish, which establish the proper cutting location. A two-axis hydraulic drive unit positions the cutter accordingly, and the cutting blade is operated using a pneumatic actuator. Position sensing of the hydraulic manipulator is done using linear magnetostrictive displacement transducers. A set of six gage-

Yes, as another example, consider a hard-disk drive (HDD) unit of a computer, as shown here. Clearly, it has mechanical and electronic components. Furthermore, energy dissipation, heat generation and cooling need the consideration of fluid and thermal domains. Accordingly, it is a multi-physics device. However, strictly, it won't be a mechatronic device unless a mechatronic approach is taken in its design and development (which is not clear from the outward examination of the device). As the final example, consider the industrial machine, which has been designed and developed by us, in my laboratory at the university, for the head removal of salmon. The conveyor, driven by an AC motor, indexes the fish in an intermittent manner. The image of each fish, captured using a digital camera, is processed to determine the geometric features of the fish, which establish the proper cutting location. A two-axis hydraulic drive unit positions the cutter accordingly, and the cutting blade is operated using a pneumatic actuator. Position sensing of the hydraulic manipulator is done using linear magnetostrictive displacement transducers. A set of six gage-

pressure transducers are installed to measure the fluid pressure in the head and rod sides of each hydraulic cylinder, and also in the supply lines. At the end of the process, a high-level imaging system determines the cutting quality, according to which adjustments are made on-line, to the parameters of the control system of the machine, to improve the machine performance. Clearly, this is a multi-domain (multi-physics) system, which involves at least the mechanical, electrical, and fluid (hydraulic and pneumatic) domains. It was designed by considering all these domains concurrently, in a systematic manner, and a "design optimization" was performed leading to a single (unique) design. So, this machine can be considered as a "mechatronic" system, in the true sense of the definition.

pressure transducers are installed to measure the fluid pressure in the head and rod sides of each hydraulic cylinder, and also in the supply lines. At the end of the process, a high-level imaging system determines the cutting quality, according to which adjustments are made on-line, to the parameters of the control system of the machine, to improve the machine performance. Clearly, this is a multi-domain (multi-physics) system, which involves at least the mechanical, electrical, and fluid (hydraulic and pneumatic) domains. It was designed by considering all these domains concurrently, in a systematic manner, and a "design optimization" was performed leading to a single (unique) design. So, this machine can be considered as a "mechatronic" system, in the true sense of the definition.

Q: So, Professor, what would be the advantages and relevance of Mechatronics to Sri Lanka?

There are many advantages, especially since "Mechatronics" is particularly relevant to developing countries like Sri Lanka and for small and emerging industries that are unable to sustain a complete team of engineers. Many such companies develop multi-physics products such as cutters, drills, vacuum cleaners, kitchen appliances, motors, and consumer products. Even though these companies may wish to retain both mechanical engineers and electrical engineers, financially they may be hard-pressed to do so. Then by hiring one mechatronic engineer, they will be able to obtain the expertise of both mechanical and electrical engineers, in a cost-effective manner.

Q: Professor would you care to share with us, one such contribution by your team to the field of Mechatronics, to inspire our readers.

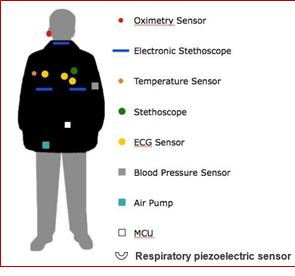

Of Course! Recent advances in sensor technologies that are applicable in human health monitoring such as biomedical nano-sensors, piezoelectric sensors, force and motion sensors, and optical/vision sensors for abnormal motion detection of humans, may be incorporated into a jacket as shown here. However, for optimal performance, the selection/development, location, mounting, and integration of the sensors should not be treated independently of the development of other aspects of the jacket. For example, a mechatronic design quotient (MDQ) may be employed to represent the "goodness" of the overall design of the jacket, where a design index is defined with respect to each design requirement (e.g., size, structure, components, cost, accuracy, speed). Then, parameters such as sensor size, interface hardware, power requirements, component location and configuration may be incorporated into the MDQ, which will improve/optimize the process of signal acquisition and processing, body conformability, weight, robustness and cost, and also will improve the speed, accuracy, and reliability of the information provided by the sensor jacket.

Of Course! Recent advances in sensor technologies that are applicable in human health monitoring such as biomedical nano-sensors, piezoelectric sensors, force and motion sensors, and optical/vision sensors for abnormal motion detection of humans, may be incorporated into a jacket as shown here. However, for optimal performance, the selection/development, location, mounting, and integration of the sensors should not be treated independently of the development of other aspects of the jacket. For example, a mechatronic design quotient (MDQ) may be employed to represent the "goodness" of the overall design of the jacket, where a design index is defined with respect to each design requirement (e.g., size, structure, components, cost, accuracy, speed). Then, parameters such as sensor size, interface hardware, power requirements, component location and configuration may be incorporated into the MDQ, which will improve/optimize the process of signal acquisition and processing, body conformability, weight, robustness and cost, and also will improve the speed, accuracy, and reliability of the information provided by the sensor jacket.

Q: So, in general, what can be considered as the benefits of a Mechatronics design?

Design optimality and better component matching; ease of system integration and enhancement; compatibility and ease of cooperation/integration with other systems; and improved efficiency, cost effectiveness, controllability, maintainability, reliability and product life. All these claims have been analytically and experimentally justified elsewhere

Q: Professor we cannot forget the contributions you have made to Sri Lanka as a reputed professional-?

Well, when the former dean of Open University of Sri Lanka (OUSL), Prof. Dayantha Wijesekera. visited me at the University of British Columbia (UBC), I suggested, among other things, introducing a curriculum of Mechatronics in Sri Lanka. Later I developed the curricula and the course material for a diploma and a degree in Mechatronics and implemented them at OUSL under the leadership of the Head of Mechanical Engineering, Mr Sarath Chandra. These programs are facilitated through such activities as those of Soft Robotics Research Group at OUSL, which you head.

I also endowed a monetary award for the student graduating top of the class, in memory of my mother. Through my research funds, I have fully supported about two dozen Sri Lankan students to study for their postgraduate degrees in Mechatronics at UBC, under my supervision. They included students from University of Moratuwa (UM), OUSL, and Sri Lanka Institute of Information Technology (SLIIT). Notable two such students are Dr. Lalith Gamage and Dr. Nalin Wickramarachchi, who after their PhD studies and a postdoctoral stint in my laboratory, returned to Sri Lanka (UM). Subsequently, Lalith established SLIIT, which has become a very successful private university, and Nalin became the Dean of Engineering at UM. It is worthy of noting here that I developed the curricula for the Mechanical Engineering and Mechatronics programs as well at SLIIT. OUSL was the first to offer a Mechatronics program in Sri Lanka. The Mechatronics programs at both OUSL and SLIIT are quite popular (and currently I have two lecturers from OUSL and SLIIT carrying out their postgraduate studies under my supervision, with full scholarships provided from my research funds).

I also endowed a monetary award for the student graduating top of the class, in memory of my mother. Through my research funds, I have fully supported about two dozen Sri Lankan students to study for their postgraduate degrees in Mechatronics at UBC, under my supervision. They included students from University of Moratuwa (UM), OUSL, and Sri Lanka Institute of Information Technology (SLIIT). Notable two such students are Dr. Lalith Gamage and Dr. Nalin Wickramarachchi, who after their PhD studies and a postdoctoral stint in my laboratory, returned to Sri Lanka (UM). Subsequently, Lalith established SLIIT, which has become a very successful private university, and Nalin became the Dean of Engineering at UM. It is worthy of noting here that I developed the curricula for the Mechanical Engineering and Mechatronics programs as well at SLIIT. OUSL was the first to offer a Mechatronics program in Sri Lanka. The Mechatronics programs at both OUSL and SLIIT are quite popular (and currently I have two lecturers from OUSL and SLIIT carrying out their postgraduate studies under my supervision, with full scholarships provided from my research funds).

Joining hands with SLIIT, I established a computer room and built a concrete paved road for the Morahela Mahavidyalaya, Sri Lanka. An on-line mentorship network called "Guna Nena Diriya" was established for the students in Sri Lanka who could obtain advice on various topics (educational, professional, personal, etc.) from Sri Lankan professionals throughout the world.

Q: To wind up, what would be the message you would like to pass on to aspiring young students and the Sri Lankan community?

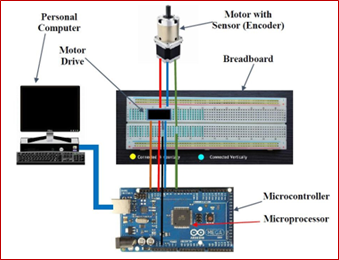

Beyond just the knowledge of using a computer, it is not difficult or costly to provide computer-integrated projects in Mechatronics even to Grade 8 students in Sri Lanka. It requires a laptop, tablet, or personal computer, which is the "host computer" and is commonly available. The hardware that is needed is quite simple and low cost. A microcontroller (e.g., Arduino), which serves as the "computer" and the "controller" of the project, in the mechatronic sense, forms the main building block. It has a microprocessor chip, which performs the main computing functions of the project, in particular. The microcontroller is connected to the host computer using a USB cable. The "pins" (actually pin slots) of the microcontroller are present at its edges and are connected to other hardware using jumper cables. A breadboard may form the intermediary role of interconnecting various hardware. I would encourage young enthusiasts to try out the following project.

Mini Project

This project concerns controlling a DC motor (the actuator). The motor has a built-in motion sensor (e.g., an optical encoder or a potentiometer). A low-cost unit (new or used) may be used for this purpose. Since the current from the microcontroller is not usually adequate to operate the motor, a drive hardware unit has to be used, as shown here.

This project concerns controlling a DC motor (the actuator). The motor has a built-in motion sensor (e.g., an optical encoder or a potentiometer). A low-cost unit (new or used) may be used for this purpose. Since the current from the microcontroller is not usually adequate to operate the motor, a drive hardware unit has to be used, as shown here.

The programming of the microcontroller, according to the required task, is done on the host computer using the microcontroller programming language (which is quite similar to C or C++ and is very easy to learn). However, the integrated development environment (IDE), which is freely available from the microcontroller web site needs to be downloaded first to the host computer. Once the program is written on the host computer, we simply download it to the microcontroller (via the USB cable), and the motor will run according to the program. Essentially, the microcontroller reads the sensor signal and computes the drive command for the motor, which is transmitted to the drive hardware. Then the drive unit generates the required current to operate the motor. All these activities of the microcontroller are performed in real time.

A project like this can be quite fun while being practical and educational even to young students. It can be carried out under the supervision of an adult (teacher, parent, older sibling, relative, etc.) who is somewhat computer savvy.

Contributed by Eng. (Mrs)Nimali Tennekoon Medagedara

BSc Eng (Hons) (Peradeniya), MPhil (SHU),MIE (SL),C.Eng., MIEEE

Senior Lecturer, Department of Mechanical Engineering

The Open University of Sri Lanka.