|

|

On the 4th of November 2015 which was Wednesday at 5.15 p.m. I presented a lecture to the Engineers of the Institution of Engineers Sri Lanka at the Wimalasurendra Auditorium, on the topic of “Designing and Construction of a Floating Production and offshore storage (FPOS) and I was pleasantly surprised at the enthusiasm and the knowledge of the young engineers who had come to listen to me. They were smart and curious, and they had a lot in common with a desire to make a change in the field of engineering. Post presentation Q&A discussion with these fascinating engineers covered a wide variety of offshore engineering issues and demonstrated the appreciation that they had for an experienced member of their profession. Following this lecture I was invited to attend a meeting with the engineers of PRDS (Petroleum Resource Development Secretariat) by the Director Ms. Preeni Withanage.

|

|

On talking to them I understood that all of them under the leadership of Mr. Saliya Wickramasuriya (an ex veteran Marketing manager from Slumberge) simply wanted to succeed in bringing this oil and gas exploit to fruition. Last thing any senior engineer could do is crush their belief. “When you hear someone say you can’t do something, know that you can and start figuring out how. Ask yourself, ‘What would I do if I weren’t afraid?’”

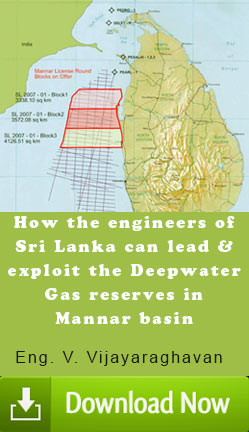

Today the pressure is on to find economically viable ways to develop the Mannar Basin fields, in the Sri-Lankan North Western waters. It was also known that two gas discoveries roughly estimated as 300bcf and 2TCF in the Mannar Basin by Cairns India Ltd has been confirmed after spending an estimated US $ 215 million for the exploration and then deciding not to develop it for the simple reason of the field existence in deep waters. Commercialization of these finds have now become a very big challenge for Sri lankan Petroleum Resources Development Secretariat (PRDS) because the fields sit in waters over 1000 meters depth. The question is can this be achieved by the engineers of Sri Lanka?

To my understanding emphasis is being placed on PRDS to secure an appropriate strategy by the present government to exploiting these reserves. My experience in this industry suggests that conventional solutions prove too costly or unsuitable for deep-water and remote fields. As such more novel and innovative engineering solutions are required here.

Marginal fields typically share one or more of the following characteristics given below, and may result in high risk to returns on capital investment; could have heightened sensitivity to product price, and/ or escalation in Capex and Opex during field development and operation.

|

Low exploitable reserves - typically 25-50 MMbbl oil (between 10,000-30,000 bo/d) or one that produces 60,000 cubic feet (1,700 m3) or less of gas per day at its maximum flow rate ) |

|

Uncertainty in extent of the proven reserves, field life, production profile or reservoir geology |

|

Difficult access and or to export – i.e. stranded or deep water assets |

|

Other factors including difficult reservoir fluid characteristics (high wax and wax appearance temperature, high concentration of H2S or CO2 etc.) |

Where these factors apply, it is often more practical to ask the question “given an assumed production profile based on estimated reserves, what is the maximum Capex that still ensures an attractive return on investment?”

|