Phasing-down the HFC Refrigerants in Sri Lanka: from Montreal Protocol to Kigali Amendment

By Eng (Dr) M. Anusha Wijewardane

As a tropical country, Sri Lanka incurs significant energy and infrastructure expenditure related to building air conditioning, industrial and commercial refrigeration, and mobile air conditioning (MAC) systems. The Refrigeration and Air Conditioning (RAC) system of a typical commercial building in Sri Lanka accounts for approximately 10-12% of the total construction cost according to building constructors’ estimations. Moreover, the air conditioning system accounts for around 50%-60% of a building’s overall energy cost. Domestic refrigerators and freezers, commercial refrigerators (bottle coolers, display coolers, chest freezers), industrial refrigerators, cold storages, room air conditioners (split and window), packaged air conditioners, rooftop systems, VRV/VRF systems (Variable Refrigerant Volume/Flow), central air conditioning systems (chillers) and mobile air conditioning systems are the RAC systems currently used in Sri Lanka. These systems use HCFCs (hydro chlorofluorocarbon), HFCs (hydrofluorocarbon), and natural refrigerants i.e., HCFC-22, R-404A, HFC-134a, R-410A, R-407C, R-507A, HFC-32, HC-600a, HC-290 and R-717.

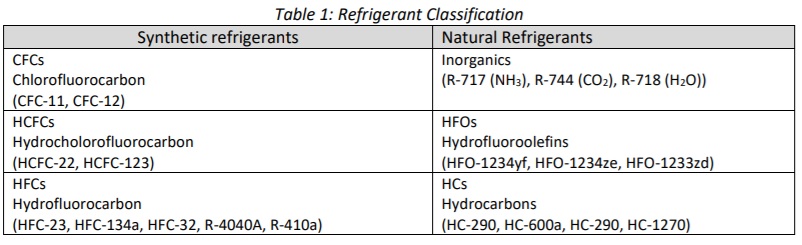

A refrigerant is the working fluid used for heat transfer in refrigeration and air conditioning systems. Refrigerants can be classified under different categories as shown in Table 1.

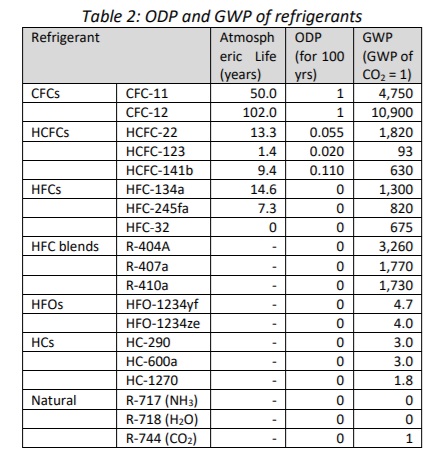

Ozone Depletion Potential (ODP) and the Global Warming Potential (GWP) of synthetic refrigerants are exceptionally higher compared to natural refrigerants as demonstrated in Table 2. Continuous emission of these refrigerants with high ODP and GWP to the atmosphere will damage the environment and consequently harm living organisms.

The Montreal Protocol was designed in 1987 to phase out the production and consumption of ozone depleting refrigerants. As a country with a commitment towards environmental protection, Sri Lanka ratified the Montreal Protocol in 1989 and completely phased-out high-ODP CFCs in 2008, two years ahead of the schedule. HCFCs have lower ODP compared to CFCs and were introduced as transition refrigerants to replace CFCs during the intensive CFC phase-out period. Currently, the HCFC phase-out is also underway and HCFCs will be phased out of the Sri Lankan market by 2030. The main strategies adopted by Sri Lanka to phase out HCFC are limiting the supply of HCFCs (imposed import bans on refrigerants), reducing the demand of HCFCs for manufacturing and servicing equipment, and limiting new demand for HCFC and reducing the emission of HCFC (imposed import bans on equipment operate on HCFCs).

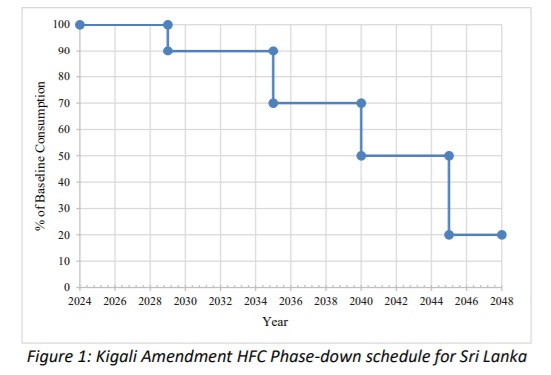

Some ODP alternatives, such as HFCs, have been proven to be powerful Greenhouse Gas (GHG) emitters with a high GWP. Therefore, the parties to the Montreal Protocol agreed to adopt Kigali Amendment to phase down HFCs in 2016. Two years later, in September 2018, Sri Lanka also ratified Kigali Amendment to phase down the consumption of HFCs, with the expectation of reaching a plateau of 20% of the baseline consumption by 2045 as shown in Figure 1.

In order to implement the obligations of Kigali Amendment, it is required to conduct a country assessment on RAC/MAC industry in Sri Lanka. Recently, the National Ozone Unit (NOU), the focal point for the Montreal protocol in Sri Lanka, published the ‘Country Assessment Report (CAR) for Implementation of the Kigali Amendment in Sri Lanka’, with the consulting support from a Team of Consultants the Dept. of Mechanical Engineering, University of Moratuwa.

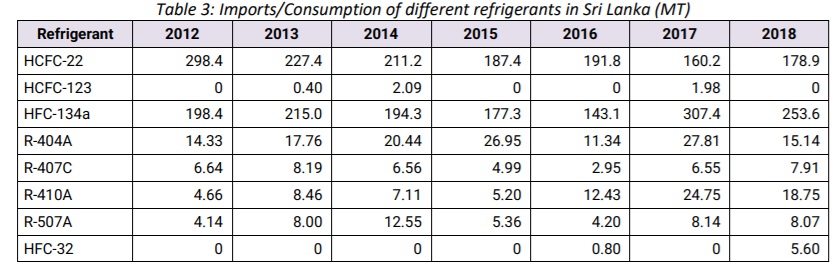

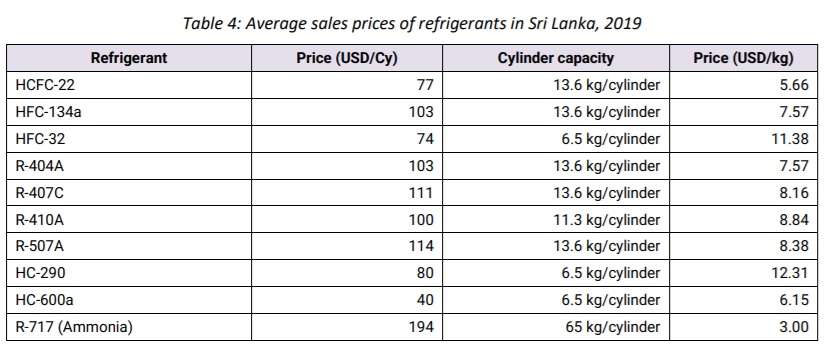

It was revealed that Sri Lanka does not produce any HFCs and instead imports them to meet all its domestic market demand. In addition, HFCs are used mainly in the Sri Lankan RAC/MAC servicing sector. Table 3 shows that the penetration of low/zero GWP refrigerants in the RAC/MAC sector is not yet significant. Refrigerant prices provided in Table 4 show that the prices of low/zero GWP refrigerant are significantly higher than those of the high-GWP refrigerants.

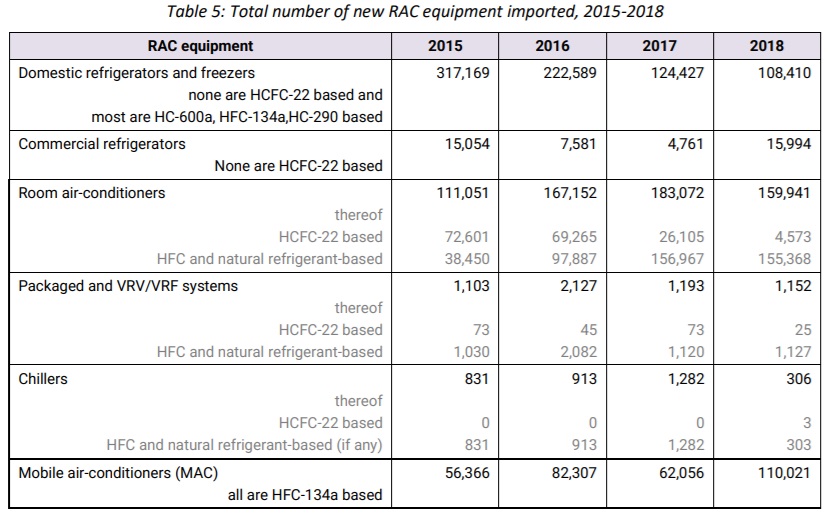

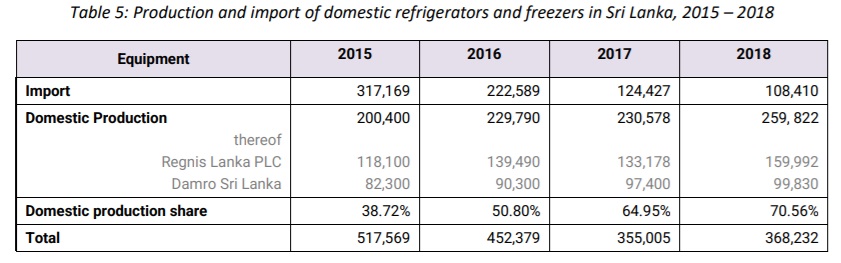

It was found that domestic refrigerator and freezer imports to Sri Lanka gradually decreased during the 2015-2018 period, mainly due to local production by Regnis Lanka PLC and Damro Sri Lanka, the two local refrigerator and freezer manufacturers with competitive prices. In 2018, the two companies used approximately 40-50 MT of HC-600a in their equipment production. Most of the imported domestic refrigerators also operate on HC-600a.

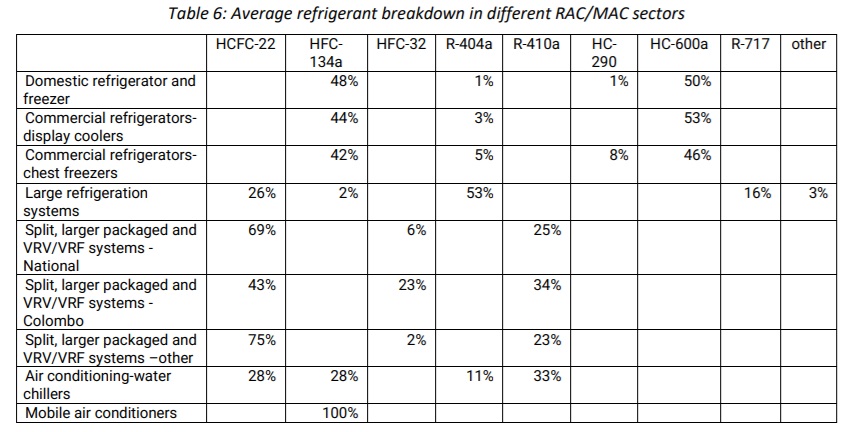

The average breakdown of refrigerant use in different RAC/MAC sectors is presented in Table 6.

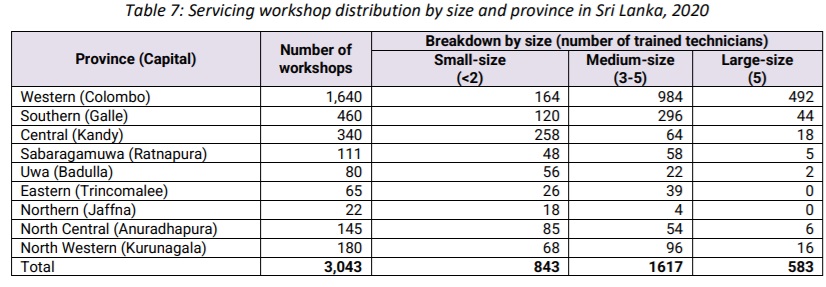

RAC/MAC servicing sector plays a vital role in refrigerant handling in Sri Lanka, since about 90% of the imported refrigerants are used for equipment servicing purposes. Table 7 presents the distribution of RAC/MAC servicing workshop in Sri Lanka.

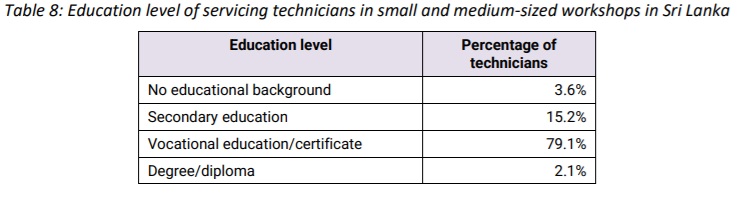

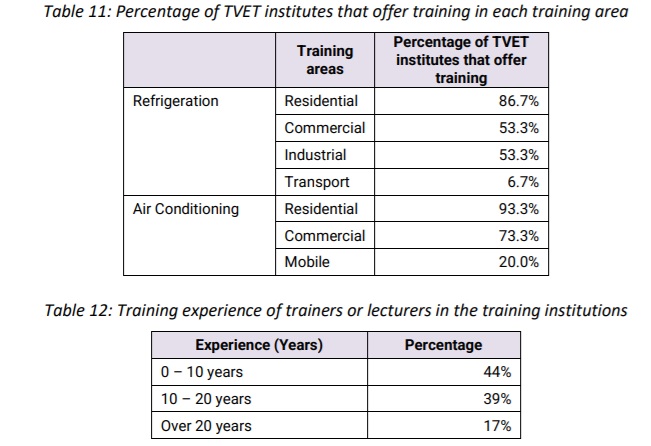

TVET Institutes, both government and private, train approximately 800 – 1,000 RAC technicians annually. However, many of them move to other countries to work once the training is completed. The table below shows the education level of servicing technicians who work in small and medium-sized workshops in Sri Lanka.

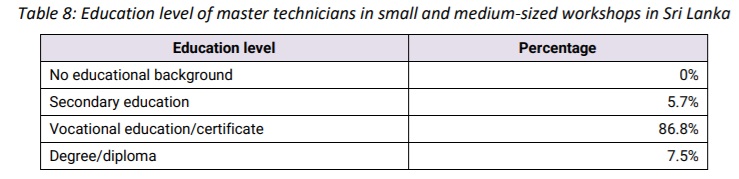

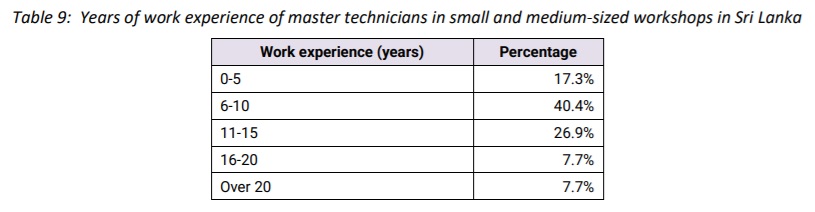

Around 80% of the technicians have received appropriate education and training in the RAC sector and approximately 20% of them have not. It was also found that a majority of the servicing technicians are comfortable working with HCFC-22, HFC-134a, R-410A, and HC-600a, while many were not very familiar with HF-290, HFC-32, R-404A, and other uncommon refrigerants. Almost all of the small and medium-size workshops have only one master technician, who is generally the owner or the manager or the most senior technician in that workshop. There are approximately 2,100 – 2,200 master technicians in Sri Lanka. The education level and the average length of work experience of these master technicians in workshops are provided in the following tables.

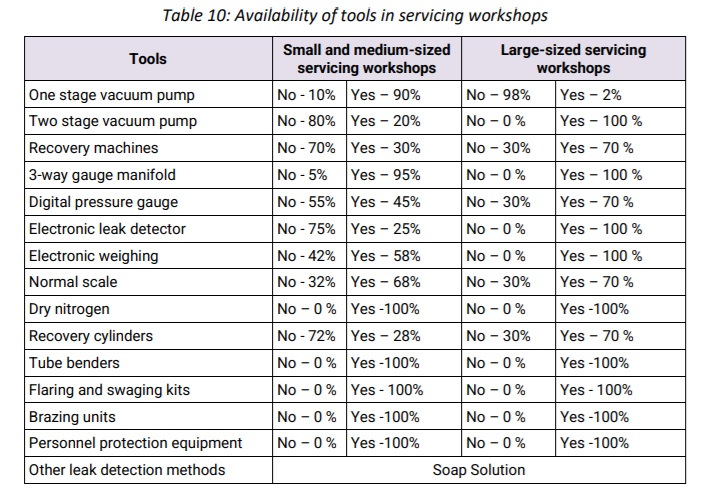

At present, more than 70% of small and medium-sized workshops in Sri Lanka release refrigerants directly to the atmosphere without recovering, recycling, or reusing. A majority of the technicians were not aware of the importance of refrigerant recovery and said they will purchase recovery devices if recovery is mandatory.

Generally, RAC courses conducted by VTA, DTET, NAITA, NYSC, CGTTI and DSS award the NVQ 3 or NVQ 4 qualification upon the completion of the training program. The duration of these National Certificate Courses is usually 12 to 18 months, either on a full-time basis or on a part-time basis. Entry-level qualification of the National Certificate of RAC Mechanic courses is 6 passes in Local GCE O/L examination including Sinhala/Tamil and mathematics. However, the RAC courses offered by SLIATE award the NVQ 5 or NVQ 6 qualifications upon completion, which are Higher National Diplomas More than 75% of the TVET institutions have only one trainer or lecturer to conduct the lecture and training sessions, and only 25% of institutions have 2-3 trainers or lecturers. Sixty-eight percent of the trainers or lecturers have NVQ 3 or NVQ 4 level education qualification and 32% have Dip.B.Tech level education. The approximate training experience of the trainers or lecturers is summarized in Table 12.

More than 50% of the trainers or lecturers need more training on the handling of new refrigerants, especially flammable refrigerants (such as hydrocarbons and HFC-32), natural refrigerants (such as R-744 and R-717), VRV/VRF systems, inverter technologies, humidifiers, chillers, and Variable Frequency Drivers (VFDs).

Implementation of the Kigali Amendment would be impossible without the collective support from the stakeholders of the RAC/MAC industry including, NOU (coordinator) and other government institutions (i.e. SL Customs, Dept. of Import and Export Control), academic institutions (i.e. NAITA, German Tech), end users (i.e. households, hotels, banks, commercial buildings, hospitals), RAC/MAC servicing workshops, refrigerant and equipment importers, and RAC equipment manufacturers and assemblers.

End users should always make sure to purchase the RAC equipment that operate on low-GWP refrigerants (i.e. HC-600a, HC-290, HFC-32). RAC equipment need regular maintenance, and hence it is necessary to ensure that a reputed/well trained RAC/MAC technician is hired for the services/repairs. Finally, RAC/MAC service technicians too need proper training and awareness about the impacts of refrigerants.

Eng (Dr) M Anusha Wijewardane holds a BSc in Mechanical Engineering, and PhD in Thermal Energy Management. She works for the Department of Mechanical Engineering, University of Moratuwa.

Eng (Dr) M Anusha Wijewardane holds a BSc in Mechanical Engineering, and PhD in Thermal Energy Management. She works for the Department of Mechanical Engineering, University of Moratuwa.