What Happened to The Unsinkable “Titanic”?

By Eng. Himalsha Dharmapala

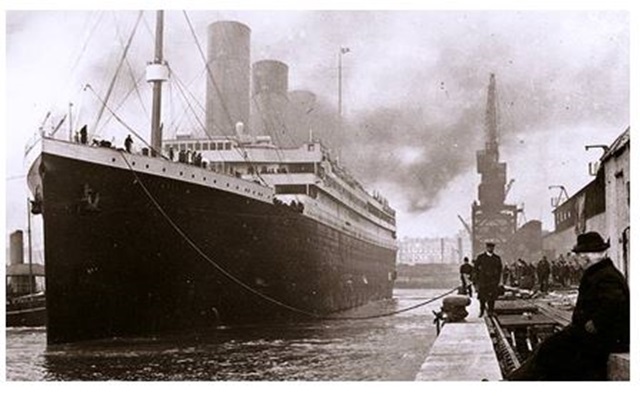

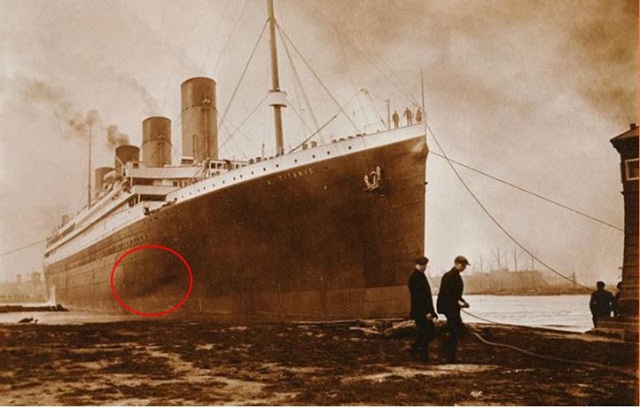

RMS TITANIC leaving Southampton to start her maiden voyage on 10th of April 1912

RMS TITANIC leaving Southampton to start her maiden voyage on 10th of April 1912

On the 10th of April 1912, ship “RMS TITANIC” started her maiden voyage from Southampton, England to New York, USA. At that time TITANIC was the largest passenger ship ever built in the world. It was owned by White Star Line Company. The ship was 230m long, 28m wide and weighed 46,000,000 kg which included a gym, swimming pool, rest rooms and other luxuries. With the reliable words of the builders’ she was called ‘the unsinkable ship’. They claimed that she cannot be sunk even under the worst conditions in the ocean. Therefore, no one out of 2200 people on board or on the ground never thought this famous girl would make 14th of April night memorable forever with the loss of 1500 people. The ship was devastated by the collision into an iceberg. Everything but only sorrow, pity and terrified memories were remained.

What caused a vessel like this to fail when it crashed into an iceberg? What is the scientific explanation to this failure? Material failures and Designing defects played major role in this scenario. Even though officers gave their full strength to avoid the collision, it all ended up having a sideswipe at iceberg and the right side of the hull was damaged nearly 100m long due to crash. When designing this kind of vessel, material should have sufficient ductility .Simply ductility means the ability to deform without breaking when having applied load (examples of good ductile materials are gold, silver and copper).After the several explorations of the Titanic wreck in 1991, scientists were able to recover pieces of metal of the ship wreck which was belonged to ship hull. These pieces of metal were faced charpy test (Impact Test) in laborites to analyze the material properties.

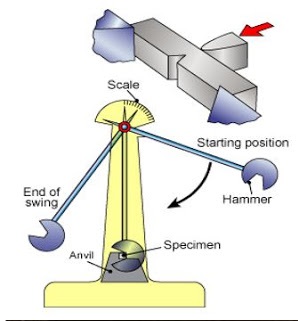

The Impact test is done by holding the metal specimen against steel pendulum and then release the steel pendulum from its starting position which allows it to swing freely and have an impact on the held specimen .Before the starting above procedure the scale reading should be set to 0 position. This reading indicates the energy absorption of the specimen.

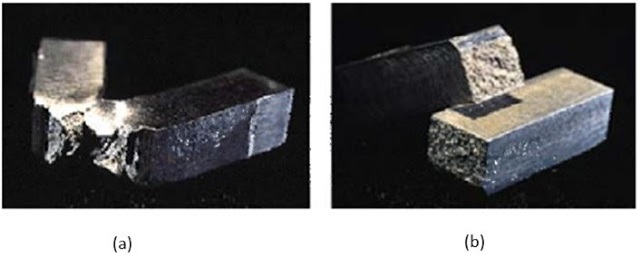

Scientists also prepared a high quality steel piece which was kept at -2°C alcohol mimicking the same ocean conditions on the night Titanic sank. Both steel pieces from the Titanic hull and prepared on the same conditions were tested in a laboratory. When prepared steel faced the test and when the steel pendulum gave a heavy impact on the prepared high-quality steel after swinging, it was not completely broken into two parts but gave only “V” shaped bend. However, when the metal piece of the ship hull was tested, due to the impact of the pendulum it was completely broken into two parts.

Figure 1. How the samples looked after the Impact Testing (a) the high quality modern steel which had been prepared for the test (b) Titanic ship hull steel from the wreck(Bassett 2000)

Figure 1. How the samples looked after the Impact Testing (a) the high quality modern steel which had been prepared for the test (b) Titanic ship hull steel from the wreck(Bassett 2000)

Therefore, this confirmed what happened to the hull steel when the ship collided into iceberg. When the ship was colliding, hull plates did not deform, which reveals that the ductility of the material is of poor condition. Unfortunately, because of the high brittleness ship hull plates shattered instead of deforming. What happened was similar to figure (b) instead of figure (a) in a much larger scale.

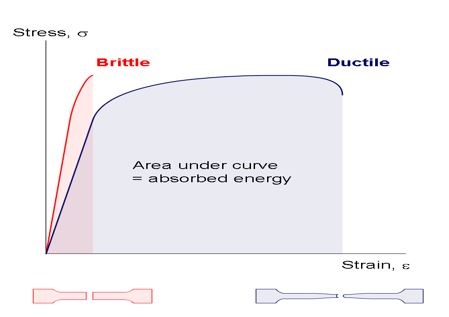

Simply brittleness means breaks with small elastic deformation without plastic deformation. Most of the time this breaking also emits a snapping sound. Also, brittle materials can absorb less amount of energy than ductile materials (examples of brittle materials are ceramic and glass).

Figure 2. Ductility vs Brittleness differences (Amgreen 2010)

Figure 2. Ductility vs Brittleness differences (Amgreen 2010)

On the other hand, the steel which had been used for making Titanic included high Sulphur content and Oxygen. Adding high Sulphur content into steel increases its brittleness. In steel when there is high level of Sulphur content, Sulphur bonds with the Magnesium in the steel which forms Magnesium Sulfide. Magnesium Sulfide causes cracks in steel. Adding Oxygen also produces similar results. This high level of Oxygen content increases the ductile to brittle transition temperature in steel. For the hull steel, this was about 25°C to 35°C which was too high. In the night that Titanic collided, temperature of the seawater was at -2°C . This low temperature also affected the ship hull to become more brittle. Therefore, due to all these reasons together resulted in ‘brittle fracture’ and above-mentioned Impact testing also proved this hypothesis.

There is also another theory to explain Titanic disaster. Irish journalist Senan Molony insisted that the Titanic ship hull was weakened before the voyage got started because of the coal fire inside the coal bunkers in the hull.

Figure 3.Titanic leaving Belfast on 2nd of April 1912. A black mark can be seen on the hull (Lewis 2017)

Figure 3.Titanic leaving Belfast on 2nd of April 1912. A black mark can be seen on the hull (Lewis 2017)

According to this ideology, because of the coal fire, temperature of the hull steel increased. The Titanic had only one hull same as most of the vessels in those days but nowadays ships have two hulls. In Titanic, place where coal was stored positioned right next to the hull. Therefore, heat of the engine may have been transferred to the hull through stored coal easily. , Molony’s conclusion was that, due to temperature changes in the hull, material structure of the hull was changed from that of the original form. Thereby nearly 30 feet long dark mark on the hull (above photograph) appeared. This area became more brittle. Iceberg crashed onto Titanic close to this area and the hull was broken easily. Although the conclusion was presented clearly, some of the scientists disagreed with this idea. They believed that this did not have an impact on brittle facture. The collision force of the iceberg would have penetrated even without having a heated hull.

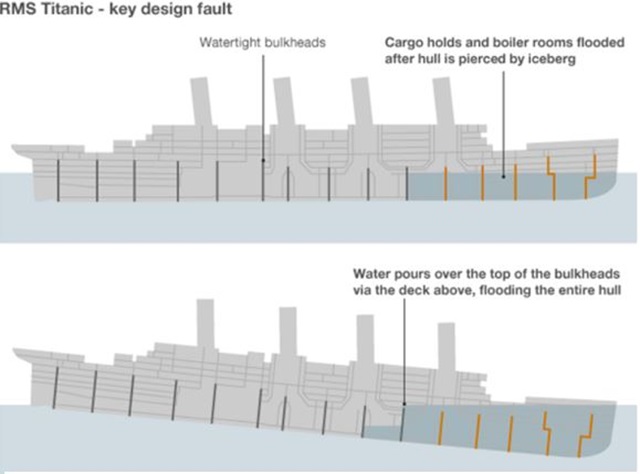

Defects of the Titanic design also played a major role in this disaster. In the ship’s lower section there were sixteen watertight compartments which could easily seal off if there was a water leakage. However, these compartments were watertight only along horizontal direction but not vertically. The top of these compartments was opened. Therefore, if one compartment was overflowed, water flowed into the next compartment and likewise all the compartments could be filled with water. This is what exactly happened when Titanic collided with the iceberg. Because of the collision, six out of sixteen compartments were damaged and started to fill the sea water. Even though they sealed off the compartments, nothing could stop the water flow horizontally due to over flow.

Figure 4. This shows how the water flow happened in compartments after the collision (Harish 2019)

Figure 4. This shows how the water flow happened in compartments after the collision (Harish 2019)

This water flow directly helped to push the ship towards the bottom of the ocean. In Scientists view, if those compartments were watertight in both horizontal and vertical directions the ship could have kept floating more than it did. This would bring sufficient time Carpathia (Carpathia was the ship which saved the survivors of Titanic) to reach the location and save everyone on board Titanic.

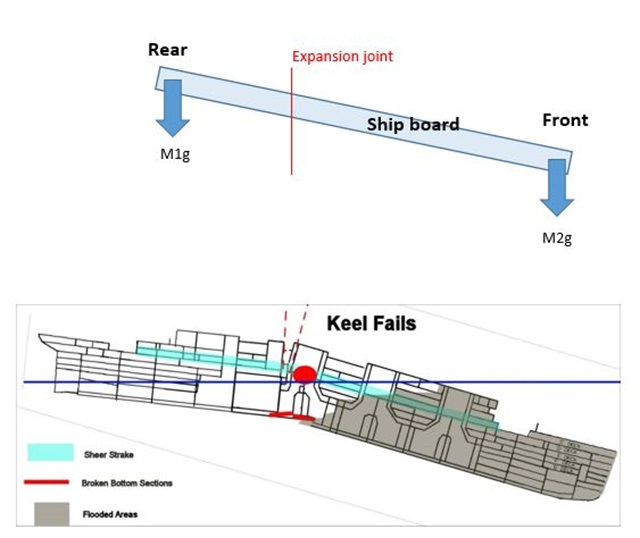

When water was rushing into the ship bow because of the weight of the water, front of the ship began to tilt down. The rear side of the ship started to lift from the water level. Titanic had three large and heavy propellers in its rear. When the rear of the ship was raised, due to the weight of the propellers, force acted in the downward direction on the board at rear. Thereby the board of the ship acted as a lever which hold two different masses in its two edges. When the lifting angle was rising and the moment it tried to pass the stress beyond the ship board metals’ maximum stress, ship board was broken into two parts from the expansion joint and both parts went down towards the bottom of the Atlantic Ocean.

Due to all these reasons and some other non-technical issues out of 2200 people only 705 survived.

-

Amgreen, 2010, Graph comparing stress–strain curves for brittle and ductile materials,photograph,viewed 16 April 2020,<https://en.wikipedia.org/wiki/Brittleness#/media/File:Brittle_v_ductile_stress-strain_behaviour.png>.

-

Bassett,V 2000, Causes and effects of the rapid sinking of the Titanic,Explanatory thesis, University of Wisconsin,viewed 18 April 2020,<http://holms.faculty.writing.ucsb.edu/titanic2.pdf>.

-

Ewers,J 2008,'The secret of how the Titanic sank',U.S.News,25 September,viewed 16 April 2020,<https://www.usnews.com/news/national/articles/2008/09/25/the-secret-of-how-the-titanic-sunk>.

-

Harish, A 2019,'Why did the titanic sink? an engineer analysis', SIMSCALE Blog, blog post,4 November, viewed 18 April 2020,<https://www.simscale.com/blog/2018/01/why-did-titanic-sink-engineer/>.

-

Lewis,D 2017,'A coal fire may have helped sink the Titanic',Smithsonian MAGAZINE,smartnews,5 January,viewed 16 April 2020,<https://www.smithsonianmag.com/smart-news/coal-fire-may-have-helped-sink-titanic-180961699/>.

Eng. Himalsha Dharmapala

Eng. Himalsha Dharmapala

Department of Manufacturing and Industrial Engineering

University of Peradeniya