40th Anniversary – Post Permanent Remedial Measures to Pattipola Summit Tunnel No 18

By Eng. Priyal de SilvaThe author wishes to place on record especially for the cognizance of the younger generation, the meticulous planning, the challenges that were faced in executing the permanent remedial measures with limited technical resources, machinery and equipment while paying immense gratitude to the staff who worked with determination and adverse climatic conditions for six weeks in Feb/ March 1981.

The tunnel which is referred to as the Tunnel no 18 or the Summit tunnel, is situated 220km from Colombo on the Upcountry railway line, and is around 01km from the highest point of the Railway Summit (1898.1m above mean sea level). This Tunnel is so situated that it demarcates the boundaries of the Nuwara Eliya District and Badulla District and also a boundary demarcation of the Central and Uva provinces. Therefore for obvious reasons tunnel is subjected to varying climatic conditions, where at times when there is rainy weather in Colombo end mouth of the tunnel, the Badulla end there is bright sun shine. These climatic conditions may have contributed to the rock strata in the tunnel being weathered and fissured.

Photo 1

Photo 1

Devices made at site to launch the base and haunch concrete panel (left)

Bucket of Front end loader modified to launch Crown concrete panel (right)

Initial collapse in 1951

The tunnel initially collapsed in 1951, when a small charge was instituted to remove a boulder which was about to foul the passage of trains. The flow of earth with mud came down in huge quantities through a cavity in the crown area of the tunnel, that the Colombo end of the tunnel was flooded due to blockage for free passage of water. The railway had to work out an immediate solution to clear the debris and resume the train service, and thus they called for the services of one of the railways most senior and capable Engineers from head office in Colombo, Mr. Edwin Black to lead the resurrection work. He was ably assisted by the District Engineer Mr. N. A. Vaitialingam and his assistant Mr. J.Paul Senaratne. The team initially erected two sleeper cribs on each side of the debris and spanned the collapsed area from beneath with steel beams, driving them from one side to the other. Later they slid on beams, steel arches made of rails, and hoisted them into position to form a steel shell across the collapsed area. The crevices between the tunnel wall and the arches were packed with sleeper planks. Once it was in position they were able to clear the earth debris. However, although the train service was resumed there were many shortcomings, where the arches were intruding on to the standard required clearance for safe passage of trains, and thus for some time trains were required to stop and start before entering the tunnel mainly to inform passengers not to keep their heads and hands out from windows as it may knock on the arches and injure them. There were also instances where in the old British coaches where the doors opened out, when the doors were not locked properly, opened and hit the rail arches, and doors were found fallen inside the tunnel. There were many fatal accidents too, that have happened during Sripada pilgrimage, when trains were crowded, some had hit their head on the arches in spite of the warnings given at the stations. Also with time it was also observed that the rail arches were fast corroding due to the moist conditions and the sleeper planks too were perishing. Thus by 1967 tunnel was again the focal point of discussion among the top railway civil engineers.

In the meantime there were many stories spreading among drivers of trains that they have seen animals such as deer and wild boar white in colour running in front of the train inside the tunnel but on approaching them they disappear, also there were big red light flashing at a distance and when drivers slow down and approach they do not find anything. There were Head guards of trains who have noticed a strange person running behind the train and waving at the guard to stop the train. So there was a hidden side, where many preferred to avoid the resurrection work fearing spiritual consequences.

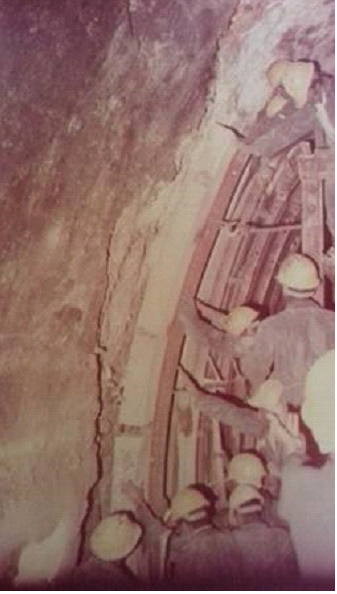

Photo 2

Photo 2

Base and Haunch concrete panels being launched into position

Suggestions for Permanent repairs

In and around mid sixties, many consultants, both foreign and local were consulted for advice on the manner of effecting permanent repairs, and one of the suggestions was to cut open the tunnel to the affected area, but this would have been very costly while disposal of earth too would have been an exercise by itself. Around the same time when an ADB team visited Sri Lanka, their advice was sought and following alternatives were suggested by them;

- Make an open cut excavation up to the cavity

- To drill from top and concrete the cavity from the top.

Mr. J. Paul Senaratne then Chief Engineer Way &Works of the Railway suggested that reinforced concrete cylinders be sunk up to a certain distance above the cavity from there onwards up to the cavity to drive steel shutters with windows and fill up the cavity with rubble through the windows and finally re -line the affected area without disrupting the train service. However this was consuming time as again disposal of earth too requires to be done and further in case steel shutters did not move due to boulders interrupting its passage, such rock requires to be blasted, and fearing that such action will give rise to a similar 1951 situation, the idea had to be dropped.

The author having passed out as a civil engineer in 1973 from University of Moratuwa, joined the Mahaweli Development Board (MDB), and was assigned to the Bowatenna Project. He worked in the Bowatenna Irrigation tunnel and gained sufficient experience in tunnel excavation and carrying out remedial measures to collapsed sections in this tunnel. In 1975 the author was recruited to the Railway Department and as a new recruit was assigned with planning and providing a design for resurrection of Pattipola tunnel due to his prior experience in the Bowatenna project. The railway had certain data at hand on soil borings carried out by Geological Survey Department which revealed that the cavity extended 25ft above the crown and had an overburden of 100ft at this point. Also soil samples revealed that the rock was fractured quarzitic gneiss with weathered feldspar. The author having studied the soil conditions, immediately sought the assistance of Specialist Engineer Geology of MDB Mr. P.M. Siththamaparapillai, and he recommended that the loose earth requires to be consolidated by pressure grouting before any attempt is made to remove the corroded rail arches. Hence in 1976 and later in 1979 on two occasions pressure grouting was done by Department of Irrigation under the direction of the author. Even after pressure grouting it was observed that the removal of rail arches were tricky because sleeper planks of 09ft in length were supported by many rail arches and as such to carry out an insitu lining a large area requires to be exposed without any support.

Photo 3

Photo 3

Crown concrete panel launched into position

Permanent repairs 1981

At this stage the author on consulting Prof. Dayantha S. Wijeyesekera of University of Moratuwa, and author’s father late Mr. L.S. de Silva (Retired General Manager Technical, Railway), then working at University of Moratuwa, advised the author to adopt precast concrete panels in arches for permanent repairs. The author considering the weight of each panel and its flexibility of handling inside the tunnel designed 02 ft reinforced concrete panels, dividing each Arch to five segments ie two bases, two haunches and a single arch type panel for the crown.

In February 1981, under author’s guidance a team was sent to Pattipola to carry out the permanent repairs. The author understanding that the implementation is very challenging and was also mindful of the health and safety of the staff. He requested the railway to provide him with one of the five motor vehicles Way& Works sub department possessed at that time and this was declined. However the author proceeded to do the work with a train load of materials and equipment.

On the very first day that the work commenced Chief Engineer visited the site and while the workmen were pulling the sleeper planks, one of them rolled over and hit a member of staff where he had to be rushed to Nuwara Eliya hospital by Chief Engineer’s vehicle. This made the Chief Engineer to allocate one of the five vehicles for this repair work until such time it was completed. The workmen thought this injury was a bad omen and insisted that the author and other staff take blessings of the God Saman, before recommencement of work, and thus it was done by attending to religious activities in the nearby Kovil constructed during temporary repairs in 1951. It was also decided at that time to construct a place for Buddhists to worship in the same location, on successful completion of Permanent repairs. Fortunately there were no accidents experienced to staff afterwards until the completion. All the oxygen and acetylene cylinders that were required to cut the rail arches were sent by train from Colombo to Nanuoya and arrangements were made to collect them from Nanuoya station by the motor trolley (motorized trolley used for inspections by staff officers). The rations for workmen were also collected in a similar way from Nanuoya, as Pattipola was a very small town without electricity which gets covered with thick midst by 5pm. The only retail shop being a small tea boutique with a few daily needs which closes by 6pm.

Initially for few days, inside the tunnel, work was carried out using carbide lamps but this could not go on, as inhaling carbide fumes made the workmen very uncomfortable and sickly. Hence the author arranged the electricity to be supplied by the generators of the diesel locomotive which was released to take heavy machinery and equipment into the tunnel. This again was not all that conducive because the diesel smoke of the locomotive engulfed the tunnel. Hence finally it was decided to couple up the locomotive with a long string of empty wagons and to keep the locomotive outside the tunnel so that diesel smoke did not come inside the tunnel.

The sequence of repair work carried out was as follows;

- Removal of rail arches on either side of the actual collapsed area.

- Driving steel plates (07nos) to cover the actual collapsed area (cavity) which was estimated to be 14ft by 08ft. steel plates were rock bolted at the ends.

- Removal of 29nos rail arches gradually, which were directly under the cavity while supporting the steel plates with temporary rail arches made out of light rails.

- Building of concrete footing on either side for a length of 40ft.

- Placing base and haunch concrete panels by a device innovated at site (see photo 1). Light rail fixed to underside of panels. Base and Haunches being launched to position, ( see photo 2) propped by Acrow prop.

- Placing of crown concrete panel by means of Front end loader, with bucket modified (see photo 3)

- Underside light rail of all panels welded to each other and concreting the crevices between panels and the wall of tunnel.

- This way 18 nos concrete arches were fixed to cover the area that had steel rail arches earlier.

- Train service resumed at restricted speed.

- After curing the concrete for 14days (in the absence of rapid hardening compound), the props and the underside light rails of panels were removed.

- Train service was resumed for normal speed.

It requires to be mentioned here that the idea of utilizing the Front end loader with the modified bucket, was an idea of a student from Dharmarajah College Kandy. His father Late Mr. D.N. Munesinghe was the Inspector of Tunnels. His suggestion was very timely and thus very much appreciated by the author, when the staff was discussing on alternatives to fix the crown concrete panel.

Conclusion

The author wishes to emphasize on the challenges that require to be taken by engineers, and how work could be accomplished with limited resources, where the engineers have the ability to be creative and innovative. The engineers shall have a vision to limit foreign involvement and thus expenditure involving foreign exchange.

The author in his career of 31 years in the railway has accomplished many important projects and finally served as the General Manager Railways, before he retired from service in Nov. 2005; he was also instrumental in putting the trains back on track under his guidance as General Manager in just 57 days after Tsunami devastation.

Reference : IESL Transactions 1981- “ Repairs to Summit (Railway) Tunnel On The Upcountry line”

Eng. Priyal de Silva

Eng. Priyal de Silva

Eng. de Silva is a Past President of the IESL, and a son of a former Past President IESL, late Eng. L.S. de Silva. He is also a Past Chairman of the Chartered Institute of Logistics and Transport, Srilanka, where his father was the founder Chairman. Eng. De Silva is the only other GMR other than legendry Eng. B.D. Rampala, to hold both posts of GMR and President IESL at the same time.