|

The advent of the Class S9 Diesel Multiple Units (DMUs) in the year 2000 marked a watershed in the annals of Sri Lankan Railways. These DMUs built by China South Locomotive & Rolling Stock Corporation had electric transmission and all subsequent DMU orders since have favoured this type of transmission. Up to that point, commencing with the Schindler Class S2 obtained in 1959, DMUs in Sri Lanka had sported hydraulic transmission. One could argue that the English Electric Class S1 of the 1930s were the very first DMUs with electric transmission on Sri Lankan soil. However, the fact that the S9s displayed a radical departure from preferences for a transmission type hitherto favoured, cannot be ignored.

Before discussing the relative merits of the different transmission types, it is pertinent to consider the characteristics of the diesel engine. Internal combustion engines, the diesel being one, develop their power by ignition within their cylinders and need to work up their revolutions prior to being connected to the drive axles of a locomotive. Thus a suitable transmission system requires to be interposed between the engine and axles, much like in road vehicles. The Americans who were the pioneers in diesel rail traction chose the electrical method of transmission, soon to be followed by the British for the majority of their initial diesel orders. The Germans on the other hand, pursued exclusively the hydraulic transmission method. Mechanical transmissions too have been employed, but only in low power applications such as rail cars and shunters.

| |

|

| |

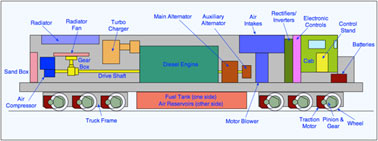

| Fig 1, General Arrangement of Diesel Electric Locomotive |

| |

|

| |

| Fig 2, Arrangement of Diesel Hydraulic Locomotive with Single Torque Converter |

| |

In diesel electrics, the diesel engine drives a generator or an alternator as is the trend currently, the current from which is fed to DC series motors on the drive axles, with rectification as the case may be, or AC asynchronous motors which are beginning to find wide application. In the case of hydraulics, the diesel engine is connected to a torque converter impeller which forces fluid within the converter on to a turbine wheel coupled to the drive axles. Static guide vanes in between the impeller and turbine multiply the torque generated. In general, two types of hydraulic transmissions are available. For lighter applications, a single torque converter with gearbox is employed, the Mekydro type, as used in the Class Y Hunslet shunters. The Voith type employs up to three torque converters, one for starting and the others for running. The Class W1 and W2 locomotives had Voith type transmissions.

The diesel scene on the railways of Sri Lanka was set in motion in the early 1950s with the arrival of the Brush Bagnall Class M1 and General Motors Class M2 locomotives, both diesel electrics. The need for development and improvement of the suburban services saw the appearance of the Schindler Class S2 and MAN Class S3 DMUs in the late 1950s. With their German origins (S2 were Swiss) they had hydraulic transmissions. Their high power, but low tractive effort, lent them for ideal operation with quick acceleration and deceleration on the flat country they normally ran on. No question these DMUs were a boon to the thousands of commuters in and around Colombo who had to get to the city for work or business on a daily basis.

In the late 1960s, it was time for Sri Lanka in keeping with other countries, to replace its ageing and uneconomical steam locomotive fleet. That farsighted and exemplary engineer B D Rampala was sufficiently impressed with the performance of the S2s and S3s to choose hydraulic transmission over electric, en masse, for the new main line diesel fleet. The result was the forty five Class W1 Henschel and fifteen Class W2 Karl Marx locomotives from West Germany and East Germany, respectively. Both had British built diesel engines, albeit of high rotational speed (1,500 rpm) as dictated by their hydraulic transmissions, Paxman 12YJXL in the W1 and Paxman 16YJXL in the W2. Their low weight (around 60 tons) and versatility gave them wide route availability with the higher power W2 being regularly employed on the heavily graded up country line. It must be added that the Class Y diesel hydraulic Hunslet shunters too appeared around this time. The rest, one might say, is history.

Much may have been stated elsewhere on the performance of the W1s and W2s and it is not the intent here to analyse in any great detail their working. However it may be relevant to note the pros and cons of the two transmission systems.

The proliferation of hydraulic locomotives in Germany is no surprise as Hermann Fottinger, a German, is accredited with the design of the first hydraulic transmission in 1905, in relation to marine propulsion. Their use in marine application declined. It took several decades till the 1930s for it to be adapted to rail traction. One of the massive advantages enjoyed by hydraulic locomotives initially was their low weight. The characteristics of hydraulic transmissions favoured the use of fast revolving diesel engines leading to the installation of more compact engines. Hydraulics, as do diesel electrics, develop maximum power at starting. As all drive axles are connected via one cardan shaft wheel slip is minimised, unlike in electrics. The ability to disseminate heat generated in the transmission more effectively than traction motors in diesel electrics, gave the hydraulics the edge in hauling heavy loads on continuous grades at low speed. Nevertheless, according to David Clough in “Hydraulic vs Electric”, in terms of transmission efficiency, figures of 70% to 80% are quoted for both hydraulics and diesel electrics. Another advantage was the low initial cost of the hydraulics.

Now for the flip side. The very fact that hydraulics employ higher revving engines tends to foster greater wear and tear and less durability. Their transmissions experience massive strains exacerbating the wear. Hydraulic drives rely on close mechanical tolerances for efficiency and even minute contamination of the hydraulic fluid can ruin the torque converter. Oil leaks too are quite common. Controls could be complicated. Additionally, exacting and strict periodic maintenance is required on the hydraulics leading to greater running costs.

The advantages of diesel electrics are well known. Foremost amongst them is that there is no mechanical connection forced to take the brunt of the power output of the engine. The transmissions are relatively simple, more robust and durable. The slower running diesel engines (maximum 750rpm in the M1s, 900rpm in the M2s vs 1,500rpm for the W1s & W2s) in the longer term, prove to be remarkably long-lasting. The DC series traction motor develops maximum torque at starting and with modern AC drives even higher tractive efforts are achievable. The latest microprocessor based controls permit close wheel slip control and AC drives obviate motor burn out. Electric drives are more forgiving of mechanical wear and precision of alignment. Long term maintenance costs have certainly favoured diesel electrics. Unlike in the pioneering days, modern diesel electrics are comparable to hydraulics in weight.

On a worldwide basis, diesel electrics have found wide application for main line operation with hydraulics relegated to shunting and low power duties (our own Y Class Hunslets are an example). As earlier stated Germany is an exception. Both the US and Britain experimented with hydraulics (Southern Pacific Railway in the US & Western Region in UK) and soon gave up in favour of diesel electrics. Single unit diesel electrics have been built to power outputs up to 6,600hp, although in recent times Voith have put out a diesel hydraulic developing around 5,000hp.

| |

|

|

|

|

The travails of the W1s and W2s in comparison with other locomotives do not require much emphasis and are well known. The W2s in particular had somewhat short lives, their high revving 16 cylinder Paxman engines proving to be very troublesome. Comparatively, the W1s fared better with the 12 cylinder version being less prone to breakdown. Even then, the transmissions were a bugbear with seals, rotational components all wearing out prematurely. |

| Fig 4, Class W3 Henschel Diesel Hydraulic Locomotive |

|

| |

|

|

The fact that the lack of periodic maintenance was very much in evidence exacerbated the situation and contributed to their demise, is no secret. In Sri Lanka with its scarce foreign resources and where the required spares had to be imported from Germany, it is not surprising that the locomotives had to be flogged to keep the railways alive with regular maintenance relegated to the background. It is a tribute to the railway staff that the W1s could be kept going for over 20 years despite the prevailing conditions. Some W1s were re-engined with Caterpillar diesels, leading to a few more years of service as the W3 Class.

The S2 and S3 DMUs provided yeoman service and clocked up hundreds of thousands of miles of running before being withdrawn. None of the subsequent classes of hydraulic DMUs fared better, all being scrapped after a very few years. In the end economics proved to be too costly to keep the hydraulics going, apart from the Class Y Hunslet shunters.

| |

|

|

|

|

On the other hand, almost all classes of diesel electrics have been going on for year after year, seemingly unstoppable, the ALSTOM M9s being an exception. Needless to mention, the legendary M2s have completed 60 years of service and even the M4s are in to their 40th year. From all the overwhelming advantages of the diesel electrics, one aspect stands out clear, the low revving diesel engine. Wherever engine revs are kept below 1,000rpm or so, long life can be expected. |

| Fig 4, Class W3 Henschel Diesel Hydraulic Locomotive |

|

| |

|

|

Sri Lankan railways have not gone in for main line hydraulic locomotives since the W1s and W2s and now, the DMUs are all diesel electric. There seems little doubt where Sri Lankan railways are heading in terms of transmission types.

On the other hand, almost all classes of diesel electrics have been going on for year after year, seemingly unstoppable, the ALSTOM M9s being an exception. Needless to mention, the legendary M2s have completed 60 years of service and even the M4s are in to their 40th year. From all the overwhelming advantages of the diesel electrics, one aspect stands out clear, the low revving diesel engine. Wherever engine revs are kept below 1,000rpm or so, long life can be expected. Sri Lankan railways have not gone in for main line hydraulic locomotives since the W1s and W2s and now, the DMUs are all diesel electric. There seems little doubt where Sri Lankan railways are heading in terms of transmission types.

It is always easy in hindsight to apportion blame to the hydraulic W1s and W2s as being a failed venture. Even Homer nods, they say. This is certainly not in any way, a suggestion of any slight on Mr Rampala’s reputation and legacy. He was a bold visionary who was not afraid to venture out in to unchartered territory and try out innovations. He was “Mr Railway”, the man who ushered in the golden era of the Sri Lankan Railways. However, one factor is clear, Sri Lankan railways will most likely, not go in for hydraulic transmissions again, at least not in the foreseeable future.

References: “Hydraulic vs Electric”, David N Clough, Ian Allen Publishing, 2011 “Hydraulic Transmission for Diesel Traction”, A Feulner, 1974

by D. U. L. Peeligama (Life Member)

|